- News & Events

- Blog

- Follow us

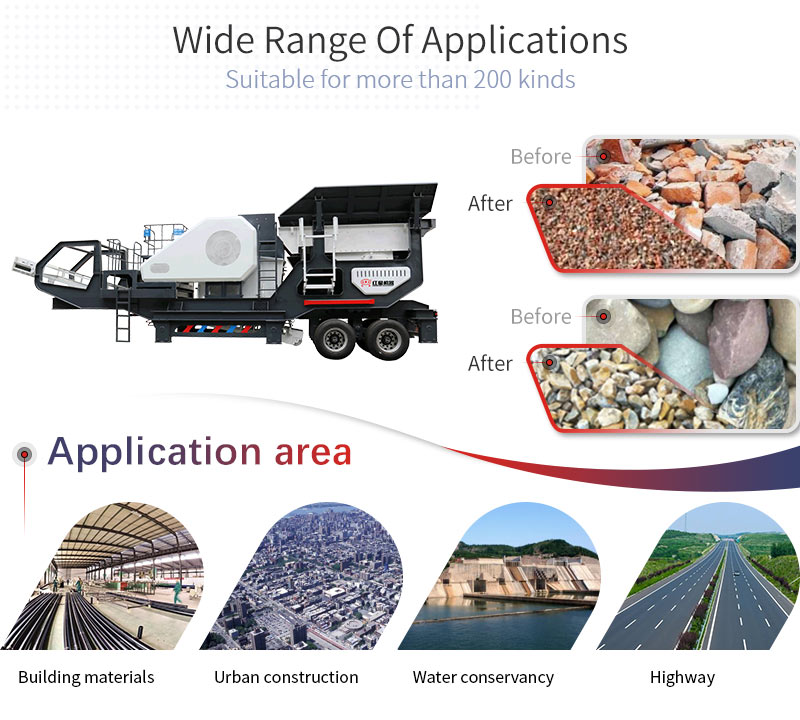

Applied materials: limestone, granite, basalt, quartz, rock, coal, iron ore, gold ore, marble, construction waste, etc.

Made in China

Two weeks delivery, custom cycle, please consult

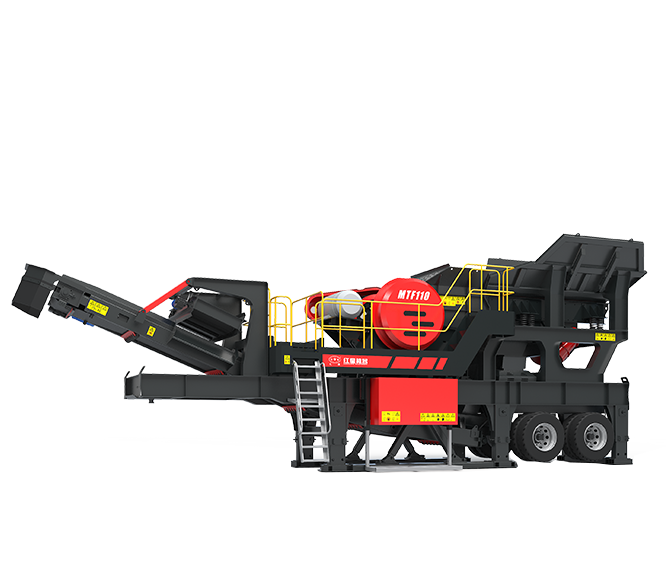

There are two main types of mobile crushers: the crawler mobile crusher and the wheeled mobile crusher, including the mobile jaw crusher, mobile impact crusher, mobile cone crusher, etc.

Mobile crusher can be used to crush cement, limestone, granite, basalt, aggregate, calcite, quartz, concrete, dolomite, bluestone, iron ore, coal gangue, construction waste, ferrosilicon. It is widely used in mining, quarry, road (railway) and bridge construction, urban construction waste disposal and other fields.

1. The chassis adopts steel ship structure with high strength and it is highly adaptable to different working sites.

2. The well-known brand motor achieves the good performance of the power system, with features of low noise and energy saving, etc.

3. According to different requirements of customers, we can provide different crushing and screening equipment and combined types of optimum design, and we fully guarantee the quality.

4. The generator set can be equipped, in order to work normally under complex situations, such as the situation of no power or sudden power off, ensuring continuous operation and reducing unnecessary loss.

The company mainly produces five series of products, including crushing equipment, sand making equipment, mineral processing equipment, milling equipment, and building materials equipment. At the same time, the company can provide customers with project design, process design, and other related services. The company has rapidly grown into a high-end mining machinery production and export base in China with scientific management methods, refined manufacturing processes, and innovative ideas.

Mobile crushing stations play a very important role in the metallurgical, chemical, building materials, and other industries. The indicators and parameters of Hongxing mobile crushing stations are strictly controlled by national standards.

If you need our latest offer, you can tell us your specific type and quantity after determining its size. Then we will send you the price. You can also contact us at sinohxjq@hxjq.com.

| Model | HX938HD86 | HX1149HD98 | HX1349HD110 | HX1349HD125 |

| Transportation lenght(mm) | 12600 | 13500 | 14500 | 15200 |

| Transportation Width(mm) | 2600 | 2700 | 2800 | 2900 |

| Transportation Height(mm) | 3870 | 4200 | 4450 | 4500 |

| Maximum Lenght(mm) | 12500 | 14000 | 16100 | 16700 |

| Maximum Width(mm) | 4100 | 4500 | 5100 | 5100 |

| Maximum Height(mm) | 4100 | 4900 | 5000 | 5300 |

| Weight(t) | 39 | 57 | 55 | 65 |

| Tire Configuration | Dualaxial | Triaxial | Triaxial | Triaxial |

| Jaw Crusher | HD86 | HD98 | HD110 | HD125 |

| Maximum Feeding Size(mm) | 500 | 550 | 660 | 800 |

| Discharge opening range | 50-150 | 75-175 | 100-200 | 125-225 |

| Capacity(t/h) | 85-275 | 110-350 | 215-510 | 280-650 |

| Vibrating Feeder | ZSW380×95 | ZSW420×110 | ZSW490×130 | ZSW490×130 |

| Main Belt Conveyor | B800×8.5m | B1000×9.5m | B1000×11m | B1200×11m |

| Side-opening Belt conveyor(optional) | B500×3m | B650×3.5m | B650×4m | B650×4m |

| Gensrt(optional) | 200KW | 250KW | 270KW | 400KW |

| Iron separator(optional) | RCYD(C)-8 | RCYD(C)-10 | RCYD(C)-10 | RCYD(C)-12 |

Model HX938HD86 and HX1149HD98

| Model | HX938HD86 | HX1149HD98 |

| Transportation lenght(mm) | 12600 | 13500 |

| Transportation Width(mm) | 2600 | 2700 |

| Transportation Height(mm) | 3870 | 4200 |

| Maximum Lenght(mm) | 12500 | 14000 |

| Maximum Width(mm) | 4100 | 4500 |

| Maximum Height(mm) | 4100 | 4900 |

| Weight(t) | 39 | 57 |

| tIRE Configuration | Dualaxial | Dualaxial |

| Jaw Crusher | HD86 | HD98 |

| Maximum Feeding Size(mm) | 500 | 550 |

| Discharge opening range | 50-150 | 75-175 |

| Capacity(t/h) | 85-275 | 110-350 |

| Vibrating Feeder | ZSW380×95 | ZSW420×110 |

| Main Belt Conveyor | B800×8.5m | B1000×9.5m |

| Side-opening Belt conveyor(optional) | B500×3m | B650×3.5m |

| Gensrt(optional) | 200KW | 250KW |

| Iron separator(optional) | RCYD(C)-8 | RCYD(C)-10 |

Model HX1349HD110 and HX1349HD125

| Model | HX1349HD110 | HX1349HD125 |

| Transportation lenght(mm) | 14500 | 15200 |

| Transportation Width(mm) | 2800 | 2900 |

| Transportation Height(mm) | 4450 | 4500 |

| Maximum Lenght(mm) | 16100 | 16700 |

| Maximum Width(mm) | 5100 | 5100 |

| Maximum Height(mm) | 5000 | 5300 |

| Weight(t) | 55 | 65 |

| Tire Configuration | Dualaxial | Dualaxial |

| Jaw Crusher | HD110 | HD125 |

| Maximum Feeding Size(mm) | 660 | 800 |

| Discharge opening range | 100-200 | 125-225 |

| Capacity(t/h) | 215-510 | 280-650 |

| Vibrating Feeder | ZSW490×130 | ZSW490×130 |

| Main Belt Conveyor | B1000×11m | B1200×11m |

| Side-opening Belt conveyor(optional) | B650×4m | B650×4m |

| Gensrt(optional) | 270KW | 400KW |

| Iron separator(optional) | RCYD(C)-10 | RCYD(C)-12 |

For customization, please contact us.

Henan Hongxing Mining Machinery Co.,Ltd.(HXJQ) covers an area of 350,000 square menters which includes 260,000 square menters of heavey duty industrial workshops.

covers an area of 350,000 square menters .

heavy duty industrial workshops.

which includes 260,000 square menters.

Is a manufacturer of high-end mining machinery in Asia.

All major ports can deliver goods

All major ports can deliver goods

Two weeks of delivery, custom cycle, please consult.

The International standard for some parts, if there are no relevant accessories in the local area, we provide engineer after-sales service.

Receive after-sales demand

Matching engineer

02Arrived at the scene