- News & Events

- Blog

- Follow us

Applied materials: limestone, granite, basalt, quartz, rock, coal, iron ore, gold ore, marble, construction waste, etc.

Made in China

Two weeks delivery, custom cycle, please consult

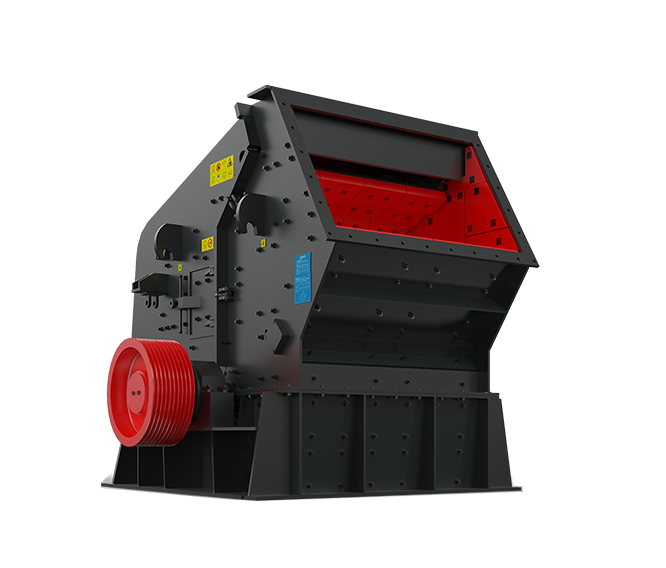

Quarry Crusher integrates the current domestic and international advanced impact crusher technology, the rotor and crushing cavity are refined design for different applications, and a large number of new high wear-resistant materials are used, which are greatly improved the performance and processing capacity of the equipment . It exhibits excellent crushing effect in applications of industries such as medium hardness and low abrasive quarrying and gravel, cement, concrete and asphalt recycling, slag recycling etc.

The motor drives the belt and pulley, and the movable jaw moves up and down through the eccentric shaft. When the movable jaw rises, the angle between the toggle plate and the movable jaw becomes larger, thereby pushing the movable jaw approaches the fixed jaw, and at the same time, the material is crushed to achieve the purpose of crushing; when the movable jaw descends, the angle between the toggle and the movable jaw becomes smaller. Under the role of pull rod and the spring, the movable jaw leaves the fixed jaw, the crushed materials are discharged from the lower mouth of the crushing cavity. With the continuous rotation of motor and the periodic motion of movable jaw, realizing mass production.

stone crusher, jaw crusher, impact crusher, hammer crusher, vibrating screen, belt conveyor, etc.

Finished product specification: 10-350 (unit: mm) Processing materials:

The final product is of nice particle shape

It is of reasonable grading and its fineness can be adjusted

It can meet the standard in the industry

The final product takes less production cost but a nice benefit.

The quarry crusher is of high automation degree, big crushing ratio, high production efficiency, big handling capacity. Besides, its final product is of cubes, less needle-like one, no crack, and high compression strength.

Maintaining the quarry crusher is easy. The quick-wear parts are made from the domestic high-strength and wear-resistant material, which have a long service life and can bring much economic benefit for clients.

The quarry crusher is successfully applied to the process of limestone, basalt, granite, pebble, etc. Its final product can meet the GB14685-2001 standard in quality, which can provide many industries the qualified aggregate, such as highway, railway, water conservancy, concrete mixing station, etc.

Henan Hongxing Mining Machinery Co.,Ltd.(HXJQ) covers an area of 350,000 square menters which includes 260,000 square menters of heavey duty industrial workshops.

covers an area of 350,000 square menters .

heavy duty industrial workshops.

which includes 260,000 square menters.

Is a manufacturer of high-end mining machinery in Asia.

All major ports can deliver goods

All major ports can deliver goods

Two weeks of delivery, custom cycle, please consult.

The International standard for some parts, if there are no relevant accessories in the local area, we provide engineer after-sales service.

Receive after-sales demand

Matching engineer

02Arrived at the scene