- News & Events

- Blog

- Follow us

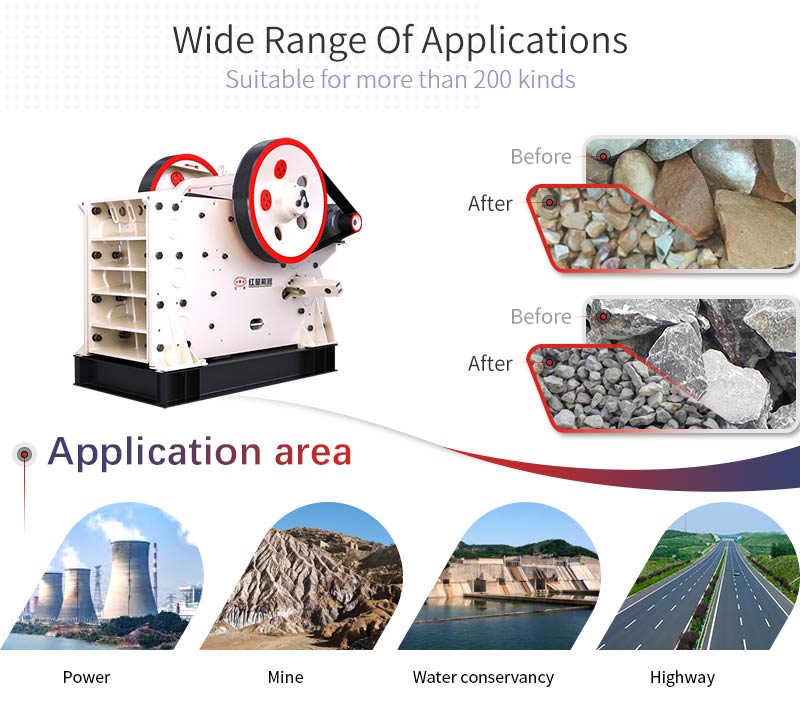

Application fields: metallurgy, chemical, building materials, electricity, transportation and other departments.

Made in China

Two weeks delivery, custom cycle, please consult

The primary crusher plays a very important role as the first step in the stone crushing line. The primary crusher has the characteristics of high crushing ratio, uniform product strength, simple mechanism, and reliable operation. It is widely used in metal and non-metal, cement, construction, sand, metallurgy and other industries.

The primary crusher can process 200 kinds of mineral ores in the primary and coarse crushing process, such as granite, basalt, limestone, rock, concrete, aggregate, gravel, dolomite and quartz. The Hot-sale models are PE400×600, PE600×900, PE900×1200, PE1200×1500 and the capacity of 16-64t/h, 50-160t/h, 220-380t/h, 400-800t/h. The maximum output can reach 1000 t/h.

pebbles, granite, basalt, limestone, quartzite, construction waste, iron ore, gold ore, copper ore, etc.

It adopts world-level manufacturing technology and high-end manufacturing materials.

More advanced movable jaw assembly makes it more durable. The movable jaw assembly uses high-quality steel casting and drives through two large-sized cast steel flywheels. In addition, the heavy eccentric shaft also adopts the forging stock which makes JC series jaw crusher extraordinarily reliable.

The bearing pedestal adopts a unitary cast steel structure. The unitary cast steel bearing pedestal can ensure comprehensive fitting with the crusher rack, and at the same time, greatly increasing the radial strength of the bearing pedestal, whereas split type bearing pedestal does not have these advantages.

Hongxing is engaged in the R&D and Manufacturing of mining equipment, including the crushing and screening equipment, and the industrial powder grinding equipment, etc. Products are exported to Eastern Europe, the Middle East, Africa, South Asia, Southeast Asia, and other countries.

With the “people-oriented, customer first, innovation” concept in management and service, except for offering clients our products, we also provide them with reasonable model selection, process allocation, and technical support, to make clients obtain the biggest benefit with a small investment. Thus, we are ready to do clients a favor at any time.

| Model | Feed opening size(mm) | Max.Feeding size (mm) | Adjustment range of discharge port (mm) | Capacity(t/h) | Rotation speed of eccentric shaft(r/min) | Power (kw) | Dimensions(L×W×H) (mm) |

| PE 150×250 | 150×250 | 125 | 10-40 | 1-3 | 268 | 4P 5.5 | 760×700×860 |

| PE 200×300 | 200×300 | 180 | 15-50 | 2-6 | 260 | 4P 7.5 | 915×780×990 |

| PE 200×350 | 200×350 | 180 | 18-60 | 3-10 | 276 | 4P 11 | 1000×914×1112 |

| PE 250×400 | 250×400 | 210 | 20-70 | 5-21 | 300 | 6P 15 | 1100×1032×1285 |

| PE 400×600 | 400×600 | 340 | 40-100 | 16-64 | 270 | 6P 30 | 1623×1736×1615 |

| PE 500×750 | 500×750 | 425 | 50-100 | 40-110 | 268 | 6P 55 | 1920×1850×1920 |

| PE 600×750 | 600×750 | 500 | 150-200 | 80-240 | 268 | 6P 55 | 2020×1850×1920 |

| PE 600×900 | 600×900 | 500 | 65-160 | 50-160 | 254 | 6P 55 | 2530×1900×2340 |

| PE 750×1060 | 750×1060 | 630 | 80-180 | 110-320 | 245 | 8P 110 | 2680×2380×2785 |

| PE 900×1200 | 900×1200 | 750 | 100-200 | 220-380 | 208 | 8P 110 | 3470×2876×3330 |

| PE1200×1500 | 1200×1500 | 1020 | 150-350 | 400-1000 | 180 | 8P 160-245 | 4850×3220×3680 |

| PE1500×1800 | 1500×1800 | 1200 | 220-350 | 500-1200 | 180 | 8P 280-380 | 5160×3660×4248 |

| PEX 150×750 | 150×750 | 120 | 18-48 | 8-25 | 320 | 4P 15 | 1170×1575×1030 |

| PEX 250×750 | 250×750 | 210 | 25-60 | 13-35 | 320 | 6P 22 | 1550×1730×1470 |

| PEX 250×1000 | 250×1000 | 210 | 25-60 | 16-52 | 330 | 6P 30 | 1580×2006×1390 |

| PEX 250×1200 | 250×1200 | 210 | 25-60 | 20-61 | 330 | 6P 37 | 1780×2214×1430 |

| PEX 300×1300 | 300×1300 | 250 | 20-90 | 16-105 | 300 | 6P 55 | 2210×2320×1723 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Max.Feeding size (mm) | Capacity (t/h) |

| PE 150×250 | 125 | 1-3 |

| PE 200×300 | 180 | 2-6 |

| PE 200×350 | 180 | 3-10 |

| PE 250×400 | 210 | 5-21 |

| PE 400×600 | 340 | 16-64 |

| PE 500×750 | 425 | 40-110 |

| PE 600×750 | 500 | 80-240 |

| PE 600×900 | 500 | 50-160 |

| PE 750×1060 | 630 | 110-320 |

| PE 900×1200 | 750 | 220-380 |

| PE 1200×1500 | 1020 | 400-1000 |

| PE 1500×1800 | 1200 | 500-1200 |

| PEX 150×750 | 120 | 8-25 |

| PEX 250×750 | 210 | 13-35 |

| PEX 250×1000 | 210 | 16-52 |

| PEX 250×1200 | 210 | 20-61 |

| PEX 300×1300 | 250 | 16-105 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

For customization, please contact us.

Henan Hongxing Mining Machinery Co.,Ltd.(HXJQ) covers an area of 350,000 square menters which includes 260,000 square menters of heavey duty industrial workshops.

covers an area of 350,000 square menters .

heavy duty industrial workshops.

which includes 260,000 square menters.

Is a manufacturer of high-end mining machinery in Asia.

All major ports can deliver goods

All major ports can deliver goods

Two weeks of delivery, custom cycle, please consult.

The International standard for some parts, if there are no relevant accessories in the local area, we provide engineer after-sales service.

Receive after-sales demand

Matching engineer

02Arrived at the scene