- News & Events

- Blog

- Follow us

Application fields: metallurgy, building materials, refractory materials and river pebbles.

Made in China

Two weeks delivery, custom cycle, please consult

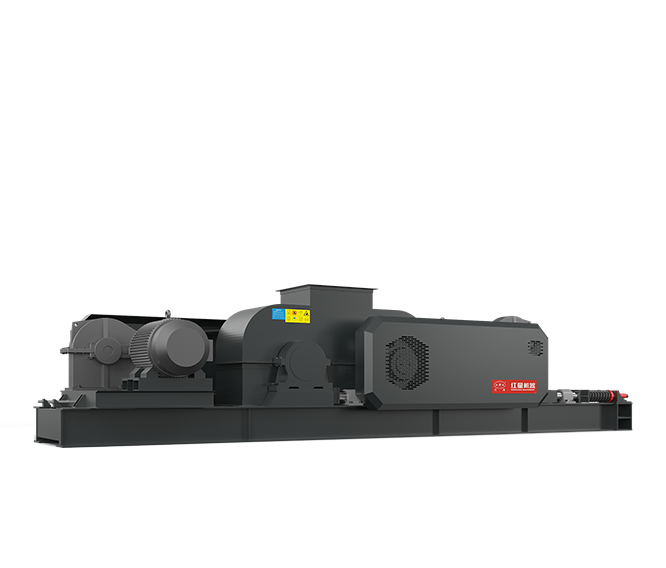

The roller crusher is a device with a long history, mature technology, and stable reliability. Suitable for fine crushing and sand making applications in industries such as cement, chemical, mining, metallurgy, building materials, and abrasives, as well as for sand making from river pebbles.

limestone, fly ash, coal powder, slag, clay. etc

Finished product specification: 10-350 (unit: mm) Processing materials:

Our company produces roller crushers and tooth roller crushers, each of which has its own advantages:

Roll Crusher

Models: 2PG0425, 2PG00640, 2PG0740, 2PG0850, 2PG1060, 2PG1260, 2PG1560

Output: 5-10t/h, 10-20t/h, 15-30t/h, 20-40t/h, 30-50t/h, 40-70t/h, 60-110t/h

Advantages: low noise, low vibration, low energy consumption, small coverage size, and simple and convenient maintenance.

Toothed Roller Crusher

Models:2PGC600×500,2PGC600×800,2PGC800×1000,2PGC1000×1000,2PGC1200×1200,2PGC1500×1200

Output: 30-60t/h, 60-100t/h, 100-160t/h, 150-200t/h, 180-250t/h, 200-300t/h

Advantages: This product becomes the first choice of the heat-engine plant to replace import crushing equipment due to its advantages of high efficiency, energy conservancy, and environment protection.

| Model | 2PG0425 | 2PG0640 | 2PG0740 | 2PG0850 | 2PG1060 | 2PG1260 | 2PG1560 |

| Roller diameter(mm) | Ф400 | Ф600 | Ф700 | Ф800 | Ф1000 | Ф1200 | Ф1500 |

| Roller width(mm) | 250 | 400 | 400 | 500 | 600 | 600 | 600 |

| Input Size(mm) | ≤25 | ≤25 | ≤25 | ≤25 | ≤30 | ≤30 | ≤30 |

| Discharging Gate(mm) | 2-8 | 2-8 | 2-8 | 2-8 | 2-10 | 2-10 | 2-10 |

| Processing capacity(t/h) | 5-10 | 10-20 | 15-30 | 20-40 | 30-50 | 40-70 | 60-110 |

| Power Models | Y132M-6 | Y180L-6 | Y200L-4 | Y225M-4 | Y250M-4 | Y315M-6 | Y315L-6 |

| Motor power(kw) | 5.5×2 | 15×2 | 30×2 | 45×2 | 55×2 | 75×2 | 110×2 |

| Roller diameter (mm) |

Input Size (mm) |

Processing capacity(t/h) |

| Ф400 | ≤25 | 5-10 |

| Ф600 | ≤25 | 10-20 |

| Ф700 | ≤25 | 15-30 |

| Ф800 | ≤25 | 20-40 |

| Ф1000 | ≤30 | 30-50 |

| Ф1200 | ≤30 | 40-70 |

| Ф1500 | ≤30 | 60-110 |

For customization, please contact us.

Henan Hongxing Mining Machinery Co.,Ltd.(HXJQ) covers an area of 350,000 square menters which includes 260,000 square menters of heavey duty industrial workshops.

covers an area of 350,000 square menters .

heavy duty industrial workshops.

which includes 260,000 square menters.

Is a manufacturer of high-end mining machinery in Asia.

All major ports can deliver goods

All major ports can deliver goods

Two weeks of delivery, custom cycle, please consult.

The International standard for some parts, if there are no relevant accessories in the local area, we provide engineer after-sales service.

Receive after-sales demand

Matching engineer

02Arrived at the scene