- News & Events

- Blog

- Follow us

Application industry: new building materials, refractory materials, fertilizers, black and non-ferrous metal dressing and glass ceramics and other production industries.

Made in China

Two weeks delivery, custom cycle, please consult

Ball mill is an important equipment in the grinding process.It ismainly placed after the crushing equipment and is a key equipment for re-crushing coarse sand and gravel materials. It has the characteristics of high crushing ratio,good reliability,strong adaptability and large processing capacity. According to the different grinding media installed,it can bedivided into ball mill,rod mill and autogenous grinding machine without media.

This machine is a skeleton ball mill driven by horizontal cylindrical turning gears, external gears, and two hoppers. The material enters the first hopper through the hollow shaft screw of the feeding equipment. The hopper has a trapezoidal or corrugated sheath, which contains steel balls that fall under the centrifugal force of the cylinder to grind the material. After rough grinding in the first hopper, the material enters the second hopper through a single-layer partition. The second hopper has a flat scale plate with steel balls for grinding the material. The powder is discharged from the grid plate to complete the grinding process.

iron ore, copper ore, gold ore,cement, lime, bauxite, calcite, barite, gypsum, quartz, slag, etc

Save energy

Rolling bearings are used instead of traditional sliding bearings to improve starting conditions,reduce the starting torque of the mill and the current during normal operation.The energy consumption of the mill dunng nommal operation is 15 to 20%lower than that of a mill using traditional bearing bushes.

Flexible design of the dischargedepartment,the feeding part has a large amount offeed

The discharge port can be selected as either grid type or overflow

type according to process requirements.

The feed inlet is equipped with a feeding spiral to force feeding,

which increases the feeding amount.

Liner castings

The structure,shape and material of the cylinder lining plate,end lin-

ing plate,compartment plate and discharge grate plate have been

tested by long-term production practice.

Use a closed system to reduce dust

The ultra-fine ball mill and classifier form a closed system,with neg-

ative pressure transportation and small dust,reducing hamm to the

human body.

Optimization of cylinder structure

Lining plates and grinding bodies can be made of alumina ceramics,

quartz,SILEX or special materials,and hard minerals are designed

to be free of iron pollution.

Dry oil spray lubrication

Large and small gears are lubricated with dry oil spray lubrication,

which has unifomm and reliable lubrication,high energy efficiency,

low fuel consumption,small footprint,no oil leakage,and no envi-

ronmental pollution.

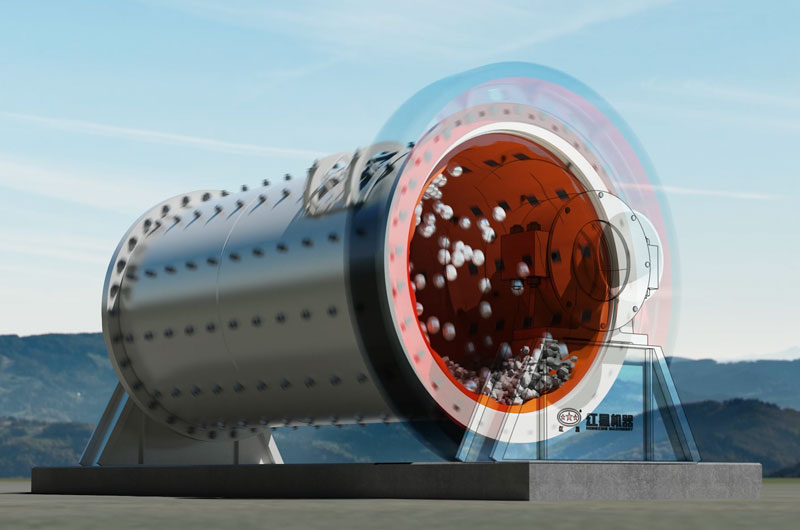

The material is fed into the mill by a drum feeder through a spiral cylinder with a hollow shaft. The grinding medium is installed in the barrel body. When the barrel body rotates, the grinding medium is attached to the wall liner surface of the barrel body due to the inertial centrifugal force. After being rotated together with the barrel body and brought to a certain height, the materials in the barrel body are broken by gravity.

In addition to the cyclic movement of ascending and falling, the grinding medium also causes sliding and rolling in the rotating cylinder body, causing grinding action between the grinding medium, the lining plate and the material to grind the material.

The company is headquartered in Zhengzhou High-tech Industrial Development Zone, Henan Province, China, covering a total area of 350,000 square meters, with 260,000 square meters of standardized heavy industrial plants, more than 600 large and medium-sized processing, riveting and assembly equipment, online employees More than 2,300 people, including the level and title of management cadres and engineering and technical personnel more than 400 people.

If you want to know more information, such as ball mill grinding concentration, grinding capacity, advantages, cost, wearing parts, discharge size, wearing parts life, equipment quality, cost performance, cost of use, maintenance rate. Please contact us or send an email to sinohxjq@hxjq.com

| Model | Cylinder | Effective Volume (m³) |

Max.Ball Loading (t) |

Speed (r/min) |

Main Motor (KW) |

|

| Diameter (mm) | Length (mm) | |||||

| MQY-1530 | 1500 | 3000.0 | 4.5 | 8 | 30 | 90 |

| MQY-1545 | 1500 | 4500.0 | 6.7 | 12 | 30 | 132 |

| MQY-1830 | 1830 | 3000.0 | 6.7 | 12 | 26.6 | 130 |

| MQY-1845 | 1830 | 4500.0 | 10.5 | 19 | 26.8 | 180 |

| MQY-2130 | 2100 | 3000.0 | 9.2 | 16 | 23.8 | 210 |

| MQY-2136 | 2100 | 3600.0 | 11 | 20 | 23.8 | 210 |

| MQY-2145 | 2100 | 4500.0 | 13.8 | 25 | 23.8 | 280 |

| MQY-2230 | 2200 | 3000.0 | 10 | 18.5 | 21.3 | 210 |

| MQY-2245 | 2200 | 4500.0 | 15.2 | 28 | 21.3 | 280 |

| MQY-2430 | 2400 | 3000.0 | 12 | 22 | 21.3 | 245 |

| MQY-2436 | 2400 | 3600.0 | 14 | 26 | 21.3 | 280 |

| MQY-2445 | 2400 | 4500.0 | 17.8 | 30 | 21.6 | 320 |

| MQY-2460 | 2400 | 6000.0 | 24 | 44 | 21.7 | 480 |

| MQY-2736 | 2700 | 3600.0 | 18 | 33 | 20.7 | 400 |

| MQY-2740 | 2700 | 4000.0 | 20.6 | 38 | 20.7 | 400 |

| MQY-2745 | 2700 | 4500.0 | 23.2 | 43 | 20.7 | 480 |

| MQY-2750 | 2700 | 5000.0 | 25.8 | 48 | 20.6 | 500 |

| MQY-2760 | 2700 | 6000.0 | 31 | 57 | 20.6 | 630 |

| MQY-3040 | 3000 | 4000.0 | 25.7 | 47 | 19 | 500 |

| MQY-3064 | 3000 | 6400.0 | 40.2 | 74 | 19 | 800 |

| MQY-3245 | 3200 | 4500.0 | 32 | 59 | 18.2 | 630 |

| MQY-3254 | 3200 | 5400.0 | 38 | 73 | 18.2 | 800 |

| MQY-3270 | 3200 | 7000.0 | 50.6 | 93 | 18.2 | 1250 |

| MQY-3645 | 3600 | 4500.0 | 40.8 | 75 | 18 | 1000 |

| MQY-3650 | 3600 | 5000.0 | 46 | 86 | 18 | 1250 |

| MQY-3660 | 3600 | 6000.0 | 54 | 102 | 18 | 1250 |

| MQY-3685 | 3600 | 8500.0 | 79 | 131 | 18 | 1800 |

| MQY-4060 | 4000 | 6000.0 | 70 | 126 | 16.9 | 1500 |

| MQY-4067 | 4000 | 6700.0 | 78 | 136 | 16.9 | 1600 |

| MQY-4361 | 4270 | 6100.0 | 80 | 144 | 15.7 | 1850 |

| MQY-4564 | 4500 | 6400.0 | 95 | 172 | 15.6 | 2000 |

| MQY-5064 | 5030 | 6400.0 | 120 | 216 | 14.4 | 2600 |

| MQY-5083 | 5030 | 8300.0 | 152 | 266 | 14.4 | 3300 |

| MQY-5585 | 5500 | 8500.0 | 187 | 338 | 13.8 | 4500 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Cylinder | Effective Volume (m³) |

Max.Ball Loading (t) |

Speed (r/min) |

Main Motor (KW) |

|

| Diameter (mm) | Length (mm) | |||||

| MQS-1530 | 1500 | 3000 | 4.5 | 9 | 30 | 110 |

| MQS-1545 | 1500 | 4500 | 6.7 | 14 | 29.6 | 155 |

| MQS-1830 | 1830 | 3000 | 6.7 | 14 | 26.6 | 155 |

| MQS-1845 | 1830 | 4500 | 10.5 | 20 | 26.8 | 210 |

| MQS-2130 | 2100 | 3000 | 8.8 | 18 | 23.8 | 210 |

| MQS-2136 | 2100 | 3600 | 11 | 22.5 | 23.8 | 245 |

| MQS-2145 | 2100 | 4500 | 13.8 | 28 | 23.8 | 280 |

| MQS-2230 | 2200 | 3000 | 10 | 20 | 21.3 | 210 |

| MQS-2245 | 2200 | 4500 | 5.2 | 30.5 | 21.4 | 320 |

| MQS-2430 | 2400 | 3000 | 12 | 25 | 21.3 | 280 |

| MQS-2436 | 2400 | 3600 | 14 | 29 | 21.4 | 320 |

| MQS-2445 | 2400 | 4500 | 7.8 | 37 | 21.4 | 380 |

| MQS-2470 | 2400 | 7000 | 28 | 58 | 21.5 | 480 |

| MQS-2736 | 2700 | 3600 | 18 | 38 | 20.7 | 400 |

| MQS-2740 | 2700 | 4000 | 20.6 | 43 | 20.7 | 450 |

| MQS-2745 | 2700 | 4500 | 23.2 | 48 | 20.7 | 480 |

| MQS-2750 | 2700 | 5000 | 25.8 | 54 | 20.6 | 560~630 |

| MQS-2760 | 2700 | 6000 | 31 | 65 | 20.6 | 630~710 |

| MQS-3040 | 3000 | 4000 | 25.7 | 54 | 19 | 560~630 |

| MQS-3064 | 3000 | 6400 | 40.2 | 84 | 19 | 1000 |

| MQS-3230 | 3200 | 3000 | 21.8 | 46 | 18.2 | 500 |

| MQS-3236 | 3200 | 3600 | 26.2 | 56 | 18.2 | 630 |

| MQS-3245 | 3200 | 4500 | 32 | 65 | 18.2 | 800 |

| MQS-3254 | 3200 | 5400 | 38 | 80 | 18.2 | 1000 |

| MQS-3640 | 3600 | 4000 | 36 | 75 | 18 | 1000 |

| MQS-3645 | 3600 | 4500 | 40.8 | 88 | 18 | 1250 |

| MQS-3650 | 3600 | 5000 | 46 | 96 | 18 | 1400 |

| MQS-3660 | 3600 | 6000 | 54 | 117 | 18 | 1400~1600 |

| MQS-4050 | 4000 | 5000 | 58 | 121 | 16.9 | 1500 |

| MQS-4060 | 4000 | 6000 | 70 | 146 | 16.9 | 1800 |

| MQS-4560 | 4500 | 6000 | 87 | 182 | 15.6 | 2300 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Cylinder | Effective Volume (m³) |

Max.Ball Loading (t) |

Speed (r/min) |

Main Motor (KW) |

|

| Diameter (mm) | Length (mm) | |||||

| MQG-1557 | 1500 | 5700 | 8.5 | 12 | 28 | 130 |

| MQG-1564 | 1500 | 6400 | 9.6 | 13 | 28 | 155 |

| MQG-1864 | 1830 | 6400 | 15 | 20 | 23.8 | 210 |

| MQG-1870 | 1830 | 7000 | 16 | 22 | 23.8 | 245 |

| MQG-1880 | 1830 | 8000 | 18.8 | 26 | 23.8 | 280 |

| MQG-2170 | 2100 | 7000 | 22 | 30 | 24.1 | 320 |

| MQG-2175 | 2100 | 7500 | 23.5 | 33 | 24.1 | 355 |

| MQG-2265 | 2200 | 6500 | 22 | 35 | 21.7 | 380 |

| MQG-2270 | 2200 | 7000 | 23.8 | 38 | 21.7 | 380 |

| MQG-2275 | 2200 | 7500 | 25.5 | 42 | 21.7 | 450 |

| MQG-2470 | 2400 | 7000 | 28 | 52 | 21.7 | 570 |

| MQG-2480 | 2400 | 8000 | 32 | 60 | 21.5 | 630 |

| MQG-2750 | 2700 | 5000 | 25.8 | 54 | 20.7 | 630 |

| MQG-2760 | 2700 | 6000 | 31 | 65 | 20.6 | 710 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Cylinder | Effective Volume (m³) |

Speed (r/min) |

Main Motor (KW) |

|

| Diameter (mm) | Length (mm) | ||||

| MZ-2410 | 2400 | 1000 | 4.5 | 22 | 55 |

| MZ-3212 | 3200 | 1200 | 9.2 | 18.2 | 160 |

| MZ-4014 | 4000 | 1400 | 16.6 | 17.6 | 245 |

| MZ-5518 | 5500 | 1800 | 34.6 | 15 | 800 |

| MZ-6433 | 6400 | 3300 | 107 | 12.8 | 2000 |

| MZ-6724 | 6700 | 2400 | 80.5 | 12.5 | 2000 |

| MZ-7525 | 7500 | 2500 | 107 | 11.4 | 2500 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Feeding capacity (t/time) |

Shell rotation speed (r/min) |

Reference motor (kw) |

Liner material |

| 600×700 | 0.05 | 50 | 2.2 | Chinaware,silicon,rubber or metal(the related motor power varied as per the different liner materials and grinding materials) |

| 800×600 | 0.075 | 42 | 3 | |

| 900×1200 | 0.2 | 38.5 | 5.5 | |

| 1300×1500 | 0.5 | 33 | 7.5 | |

| 1500×1800 | 1.2 | 28.5 | 11 | |

| 1800×2000 | 1.5 | 24 | 15 | |

| 2600×2800 | 5 | 16.5 | 37 | |

| 3000×3800 | 10 | 14.5 | 57.2 | |

| 3200×4600 | 15 | 13.5 | 75 |

| Model | Effective Volume (m³) |

Max.Ball Loading (t) |

Main Motor (KW) |

| MQY-1530 | 4.5 | 8 | 90 |

| MQY-1545 | 6.7 | 12 | 132 |

| MQY-1830 | 6.7 | 12 | 130 |

| MQY-1845 | 10.5 | 19 | 180 |

| MQY-2130 | 9.2 | 16 | 210 |

| MQY-2136 | 11 | 20 | 210 |

| MQY-2145 | 13.8 | 25 | 280 |

| MQY-2230 | 10 | 18.5 | 210 |

| MQY-2245 | 15.2 | 28 | 280 |

| MQY-2430 | 12 | 22 | 245 |

| MQY-2436 | 14 | 26 | 280 |

| MQY-2445 | 17.8 | 30 | 320 |

| MQY-2460 | 24 | 44 | 480 |

| MQY-2736 | 18 | 33 | 400 |

| MQY-2740 | 20.6 | 38 | 400 |

| MQY-2745 | 23.2 | 43 | 480 |

| MQY-2750 | 25.8 | 48 | 500 |

| MQY-2760 | 31 | 57 | 630 |

| MQY-3040 | 25.7 | 47 | 500 |

| MQY-3064 | 40.2 | 74 | 800 |

| MQY-3245 | 32 | 59 | 630 |

| MQY-3254 | 38 | 73 | 800 |

| MQY-3270 | 50.6 | 93 | 1250 |

| MQY-3645 | 40.8 | 75 | 1000 |

| MQY-3650 | 46 | 86 | 1250 |

| MQY-3660 | 54 | 102 | 1250 |

| MQY-3685 | 79 | 131 | 1800 |

| MQY-4060 | 70 | 126 | 1500 |

| MQY-4067 | 78 | 136 | 1600 |

| MQY-4361 | 80 | 144 | 1850 |

| MQY-4564 | 95 | 172 | 2000 |

| MQY-5064 | 120 | 216 | 2600 |

| MQY-5083 | 152 | 266 | 3300 |

| MQY-5585 | 187 | 338 | 4500 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Effective Volume (m³) |

Max.Ball Loading (t) |

Speed (r/min) |

| MQS-1530 | 4.5 | 9 | 30 |

| MQS-1545 | 6.7 | 14 | 29.6 |

| MQS-1830 | 6.7 | 14 | 26.6 |

| MQS-1845 | 10.5 | 20 | 26.8 |

| MQS-2130 | 8.8 | 18 | 23.8 |

| MQS-2136 | 11 | 22.5 | 23.8 |

| MQS-2145 | 13.8 | 28 | 23.8 |

| MQS-2230 | 10 | 20 | 21.3 |

| MQS-2245 | 5.2 | 30.5 | 21.4 |

| MQS-2430 | 12 | 25 | 21.3 |

| MQS-2436 | 14 | 29 | 21.4 |

| MQS-2445 | 7.8 | 37 | 21.4 |

| MQS-2470 | 28 | 58 | 21.5 |

| MQS-2736 | 18 | 38 | 20.7 |

| MQS-2740 | 20.6 | 43 | 20.7 |

| MQS-2745 | 23.2 | 48 | 20.7 |

| MQS-2750 | 25.8 | 54 | 20.6 |

| MQS-2760 | 31 | 65 | 20.6 |

| MQS-3040 | 25.7 | 54 | 19 |

| MQS-3064 | 40.2 | 84 | 19 |

| MQS-3230 | 21.8 | 46 | 18.2 |

| MQS-3236 | 26.2 | 56 | 18.2 |

| MQS-3245 | 32 | 65 | 18.2 |

| MQS-3254 | 38 | 80 | 18.2 |

| MQS-3640 | 36 | 75 | 18 |

| MQS-3645 | 40.8 | 88 | 18 |

| MQS-3650 | 46 | 96 | 18 |

| MQS-3660 | 54 | 117 | 18 |

| MQS-4050 | 58 | 121 | 16.9 |

| MQS-4060 | 70 | 146 | 16.9 |

| MQS-4560 | 87 | 182 | 15.6 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Effective Volume (m³) |

Max.Ball Loading (t) |

Speed (r/min) |

| MQG-1557 | 8.5 | 12 | 28 |

| MQG-1564 | 9.6 | 13 | 28 |

| MQG-1864 | 15 | 20 | 23.8 |

| MQG-1870 | 16 | 22 | 23.8 |

| MQG-1880 | 18.8 | 26 | 23.8 |

| MQG-2170 | 22 | 30 | 24.1 |

| MQG-2175 | 23.5 | 33 | 24.1 |

| MQG-2265 | 22 | 35 | 21.7 |

| MQG-2270 | 23.8 | 38 | 21.7 |

| MQG-2275 | 25.5 | 42 | 21.7 |

| MQG-2470 | 28 | 52 | 21.7 |

| MQG-2480 | 32 | 60 | 21.5 |

| MQG-2750 | 25.8 | 54 | 20.7 |

| MQG-2760 | 31 | 65 | 20.6 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Effective Volume (m³) |

Speed (r/min) |

Main Motor (KW) |

| MZ-2410 | 4.5 | 22 | 55 |

| MZ-3212 | 9.2 | 18.2 | 160 |

| MZ-4014 | 16.6 | 17.6 | 245 |

| MZ-5518 | 34.6 | 15 | 800 |

| MZ-6433 | 107 | 12.8 | 2000 |

| MZ-6724 | 80.5 | 12.5 | 2000 |

| MZ-7525 | 107 | 11.4 | 2500 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Feeding capacity (t/time) |

Shell rotation speed (r/min) |

| 600×700 | 0.05 | 50 |

| 800×600 | 0.075 | 42 |

| 900×1200 | 0.2 | 38.5 |

| 1300×1500 | 0.5 | 33 |

| 1500×1800 | 1.2 | 28.5 |

| 1800×2000 | 1.5 | 24 |

| 2600×2800 | 5 | 16.5 |

| 3000×3800 | 10 | 14.5 |

| 3200×4600 | 15 | 13.5 |

For customization, please contact us.

Henan Hongxing Mining Machinery Co.,Ltd.(HXJQ) covers an area of 350,000 square menters which includes 260,000 square menters of heavey duty industrial workshops.

covers an area of 350,000 square menters .

heavy duty industrial workshops.

which includes 260,000 square menters.

Is a manufacturer of high-end mining machinery in Asia.

All major ports can deliver goods

All major ports can deliver goods

Two weeks of delivery, custom cycle, please consult.

The International standard for some parts, if there are no relevant accessories in the local area, we provide engineer after-sales service.

Receive after-sales demand

Matching engineer

02Arrived at the scene