- News & Events

- Blog

- Follow us

Application fields: Wotetrack cone crusher station is widely applied in metallurgical, construction, road building, chemical and phosphatic industry.

Made in China

Two weeks delivery, custom cycle, please consult

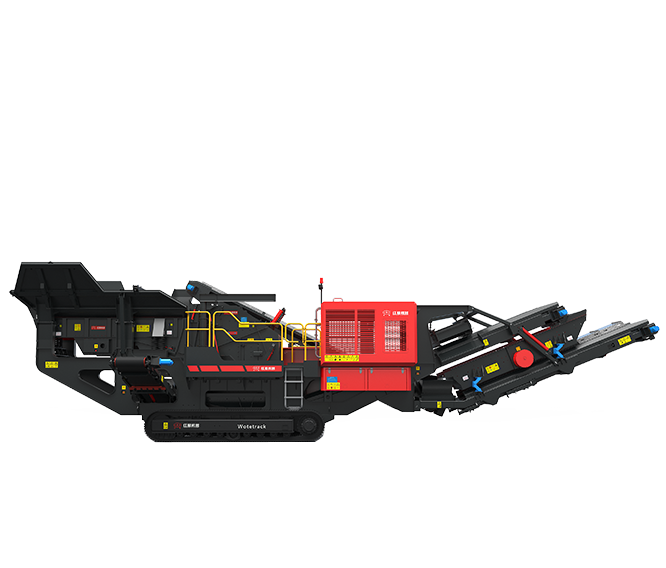

The wheeled mobile cone crusher is composed of a high-efficiency cone crusher, a high-performance vibrating screen, a belt conveyor, a motor and a control box. It is mainly used for recycling of mines, coal mines, garbage and construction waste, earth and stone works, urban infrastructure, roads or construction sites. The mobile cone crusher is mainly used in the field of fine crushing. In the production of sand and gravel, it produces higher hardness and finer grain sand and gravel products according to different stones and the use of finished products.

The material is evenly conveyed into the cone crusher through the feeder, and after the material is initially crushed by cone crusher, the closed circuit system is formed by the circular vibrating screen to realize the cyclic crushing of the material. The finished products are output by the conveyor for continuous crushing. The wheeled mobile cone crusher can remove the circular vibrating screen according to the actual production needs, and realize the primary crushing of the material directly, and it can be used with other crushing equipments, and the operation is convenient and flexible.

Wotetrack cone crusher station is suitable for hard and mid-hard rocks and ores, such as iron ores, copper ores, limestone, quartz, granite, gritstone, etc.

Finished product specification: 10-350 (unit: mm) Processing materials:

1. Incorporated design.

2. Truck mounted.

3. Quick road transportation.

4. With support legs on truck, quick to set-up.

5. Maneuverability.

1. The crushed materials are of equal size,thus reducing circulating load.

2. Large and medium-sized crushers adopt hydraulic chamber-cleaning systems, which will help reduce the down time.

3. Cone crushers with different chambers are available, to meet our customers' requirements.

| Model | WT160SC | WT250SC | WT300HPM | WT400HPM | |

| Dimensions of Transmission Devices | Length | 16800mm | 19000mm | 19000mm | 19500mm |

| Width | 3500mm | 3600mm | 3900mm | 3900mm | |

| Height | 3700mm | 3800mm | 3800mm | 3800mm | |

| Weight | 50t | 60t | 55t | 65t | |

| Belt Conveyor | Hopper Volume | 3m³ | 3m³ | 3m³ | 3m³ |

| Loading Height | 2600m | 2600m | 2600m | 2800m | |

| Loading Width | 1900mm | 1900mm | 1900mm | 1900mm | |

| Dimensions(Width×Length) | 1000×6300mm | 1000×6300mm | 1000×6300mm | 1200×6500mm | |

| Crusher | Model | SC160 | SC250 | HP300 | HP400 |

| Inlet Dimensions | 75-360mm | 75-450mm | 60-200mm | 68-280mm | |

| Max.Feeding Size | 360mm | 450mm | 200mm | 280mm | |

| Min. Discharging Size | 8-25mm | 8-35mm | 8-45mm | 8-51mm | |

| Main Belt Conveyor | Dimensions(Width×Length) | 1000×9000mm | 1000×10000mm | 1000×10000mm | 1000×11000mm |

| Dumping Height | 3100mm | 3490mm | 3490mm | 3690mm | |

| Secondary Screen | Dumping Height | 4200mm | 4200mm | 4400mm | 4400mm |

| Model | HX1536 | HX1536 | HX1536 | HX1536 | |

| Sieve Dimensions | 1500×3600mm | 1500×3600mm | 1500×3600mm | 1500×3600mm | |

| Belt Conveyors at the Bottom | Dimensions(Width×Length) | 1000×5600mm | 1000×5600mm | 1000×5600mm | 1000×6500mm |

| Dumping Height | 3020mm | 3020mm | 3020mm | 3300mm | |

| Belt Conveyors to the Sieve | Dimensions(Width×Length) | 650×2100mm | 650×2100mm | 650×2100mm | 650×2100mm |

| Dumping Height | 1370mm | 1370mm | 1370mm | 1370mm | |

| Belt Conveyors for Discharging Material | Dimensions(Width×Length) | 650×10000mm | 650×10000mm | 650×11000mm | 650×11000mm |

| Dumping Height | 4200mm | 4200mm | 4400mm | 4400mm | |

| Diesel Engine | Power | 96kw | 132kw | 106kw | 132kw |

| Manufacturer | Carter Perkins | Carter Perkins | Carter Perkins | Carter Perkins | |

| The Main Machine | Power | 207.12kw | 297.12kw | 267.12kw | 362.12kw |

| Ways of Controlling | Wired/Wireless (optional) | Wired/Wireless (optional) | Wired/Wireless (optional) | Wired/Wireless (optional) | |

Model WT160SC and WT250SC

| Model | WT160SC | WT250SC | |

| Dimensions of Transmission Devices | Length | 16800mm | 19500mm |

| Width | 3500mm | 3600mm | |

| Height | 3700mm | 3800mm | |

| Weight | 50t | 60t | |

| Belt Conveyor | Hopper Volume | 3m³ | 3m³ |

| Loading Height | 2600m | 2600m | |

| Loading Width | 1900mm | 1900mm | |

| Dimensions(Width×Length) | 1000×6300mm | 1000×6300mm | |

| Crusher | Model | SC160 | HP400 |

| Inlet Dimensions | 75-360mm | 75-450mm | |

| Max.Feeding Size | 360mm | 450mm | |

| Min. Discharging Size | 8-25mm | 8-35mm | |

| Main Belt Conveyor | Dimensions(Width×Length) | 1000×9000mm | 1000×11000mm |

| Dumping Height | 3100mm | 3490mm | |

| Secondary Screen | Dumping Height | 4200mm | 4400mm |

| Model | HX1536 | HX1536 | |

| Sieve Dimensions | 1500×3600mm | 1500×3600mm | |

| Belt Conveyors at the Bottom | Dimensions(Width×Length) | 1000×5600mm | 1000×6500mm |

| Dumping Height | 3020mm | 3020mm | |

| Belt Conveyors to the Sieve | Dimensions(Width×Length) | 650×2100mm | 650×2100mm |

| Dumping Height | 1370mm | 1370mm | |

| Belt Conveyors for Discharging Material | Dimensions(Width×Length) | 650×10000mm | 650×10000mm |

| Dumping Height | 4200mm | 4200mm | |

| Diesel Engine | Power | 96kw | 132kw |

| Manufacturer | Carter Perkins | Carter Perkins | |

| The Main Machine | Power | 207.12kw | 362.12kw |

| Ways of Controlling | Wired/Wireless (optional) | Wired/Wireless (optional) | |

Model WT300HPM and WT400HPM

| Model | WT300HPM | WT400HPM | |

| Dimensions of Transmission Devices | Length | 19000mm | 19500mm |

| Width | 3900mm | 3900mm | |

| Height | 3800mm | 3800mm | |

| Weight | 55t | 65t | |

| Belt Conveyor | Hopper Volume | 3m³ | 3m³ |

| Loading Height | 2600m | 2800m | |

| Loading Width | 1900mm | 1900mm | |

| Dimensions(Width×Length) | 1000×6300mm | 1200×6500mm | |

| Crusher | Model | HP300 | HP400 |

| Inlet Dimensions | 60-200mm | 68-280mm | |

| Max.Feeding Size | 200mm | 280mm | |

| Min. Discharging Size | 8-45mm | 8-51mm | |

| Main Belt Conveyor | Dimensions(Width×Length) | 1000×10000mm | 1000×11000mm |

| Dumping Height | 3490mm | 3690mm | |

| Secondary Screen | Dumping Height | 4400mm | 4400mm |

| Model | HX1536 | HX1536 | |

| Sieve Dimensions | 1500×3600mm | 1500×3600mm | |

| Belt Conveyors at the Bottom | Dimensions(Width×Length) | 1000×5600mm | 1000×6500mm |

| Dumping Height | 3020mm | 3300mm | |

| Belt Conveyors to the Sieve | Dimensions(Width×Length) | 650×2100mm | 650×2100mm |

| Dumping Height | 1370mm | 1370mm | |

| Belt Conveyors for Discharging Material | Dimensions(Width×Length) | 650×11000mm | 650×11000mm |

| Dumping Height | 4400mm | 4400mm | |

| Diesel Engine | Power | 106kw | 132kw |

| Manufacturer | Carter Perkins | Carter Perkins | |

| The Main Machine | Power | 267.12kw | 362.12kw |

| Ways of Controlling | Wired/Wireless (optional) | Wired/Wireless (optional) | |

For customization, please contact us.

Henan Hongxing Mining Machinery Co.,Ltd.(HXJQ) covers an area of 350,000 square menters which includes 260,000 square menters of heavey duty industrial workshops.

covers an area of 350,000 square menters .

heavy duty industrial workshops.

which includes 260,000 square menters.

Is a manufacturer of high-end mining machinery in Asia.

All major ports can deliver goods

All major ports can deliver goods

Two weeks of delivery, custom cycle, please consult.

The International standard for some parts, if there are no relevant accessories in the local area, we provide engineer after-sales service.

Receive after-sales demand

Matching engineer

02Arrived at the scene