- News & Events

- Blog

- Follow us

Application fields: Calcium carbonate crushing processing, gypsum powder processing, power plant desulfurization, non-metallic mineral powder, coal powder preparation, etc.

Made in China

Two weeks delivery, custom cycle, please consult

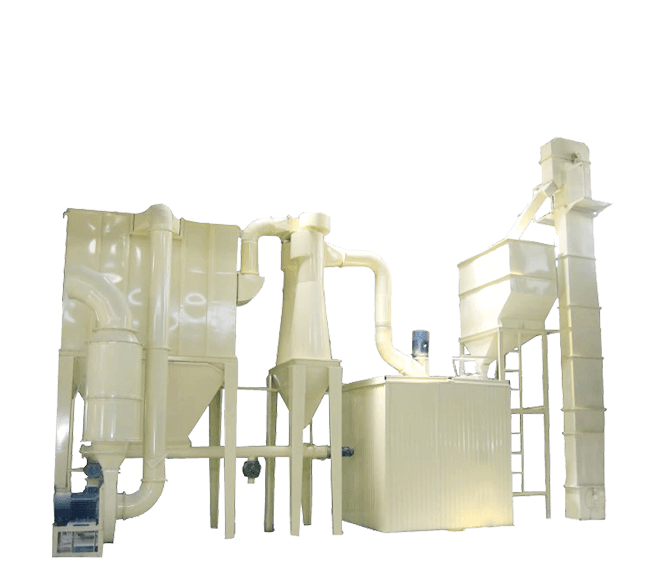

Three-ring medium-speed micro grinding mill is a new type of ultrafine grinding machine, which adopts the method of grading continuous grinding, and carries out repeated cycle grinding for materials at the same time. The finished product has finer particle size and higher efficiency and can be used for ultrafine grinding of various non-flammable and explosive brittle materials with Mohs hardness no higher than grade 5. Compared with the traditional Raymond mill, it has the advantages of fine particle size and low energy consumption.

limestone, calcite, calcium carbonate, dolomite, barite, talc, gypsum, diabase, quartz, bentonite, etc.

High Final Product’s Fineness : this machine adopts grading grinding method. The fineness of finished products can reach d97≤5μm at a time.

Long Service Life : its wear parts have a longer service life than those of the other ordinary powder grinding equipment, which can generally be more than one year.

No pollution : high-efficiency pulse dust collector, no dust pollution in operation.

High efficiency and low consumption : under the same condition, the output is 40% higher than that of airflow mill.

High Finished Product Fineness

This machine adopts graded grinding, the finished product has high fineness, and the final fineness can reach d97≤5μm at one time.

Reliable and Safe Work

There are no rolling bearings and no screws in the grinding chamber. There is no problem that the bearing and its seal are vulnerable and the screw is easy to loose and destroy the machine.

Long Lasting

In the case of the same fineness of materials and finished products, it has a longer service life than the wear parts of ordinary mill equipment, generally up to 1 year.

If you are interested in our company or products, welcome to visit our company and factories; you can also get in contact with us through online customer services, inquiry form, e-mail and telephones. Our engineer will provide products information, specific solution and good service for you as soon as possible.

| Mesh Model | HXM-1021 | HXM-800 | ||

| Output(kg/h) | Power(kw/h) | Output(kg/h) | Power(kw/h) | |

| 400 | 6000-7000 | 22 | 4000-5000 | 27 |

| 800 | 3000-3500 | 45 | 1800-2100 | 60 |

| 1250 | 2000-2500 | 70 | 1200-1500 | 95 |

| 1500 | 1800-2000 | 73 | 1000-1200 | 110 |

| 1800 | 1500-1800 | 90 | 800-1000 | 136 |

| 2500 | 1200-1300 | 120 | 600-800 | 175 |

| 3000 | 900-1100 | 145 | 500-700 | 200 |

| Mesh Model | HXM-1021 | |

| Output(kg/h) | Power(kw/h) | |

| 400 | 6000-7000 | 22 |

| 800 | 3000-3500 | 45 |

| 1250 | 2000-2500 | 70 |

| 1500 | 1800-2000 | 73 |

| 1800 | 1500-1800 | 90 |

| 2500 | 1200-1300 | 120 |

| 3000 | 900-1100 | 145 |

| Mesh Model | HXM-800 | |

| Output(kg/h) | Power(kw/h) | |

| 400 | 4000-5000 | 27 |

| 800 | 1800-2100 | 60 |

| 1250 | 1200-1500 | 95 |

| 1500 | 1000-1200 | 110 |

| 1800 | 800-1000 | 136 |

| 2500 | 600-800 | 175 |

| 3000 | 500-700 | 200 |

For customization, please contact us.

Henan Hongxing Mining Machinery Co.,Ltd.(HXJQ) covers an area of 350,000 square menters which includes 260,000 square menters of heavey duty industrial workshops.

covers an area of 350,000 square menters .

heavy duty industrial workshops.

which includes 260,000 square menters.

Is a manufacturer of high-end mining machinery in Asia.

All major ports can deliver goods

All major ports can deliver goods

Two weeks of delivery, custom cycle, please consult.

The International standard for some parts, if there are no relevant accessories in the local area, we provide engineer after-sales service.

Receive after-sales demand

Matching engineer

02Arrived at the scene