- News & Events

- Blog

- Follow us

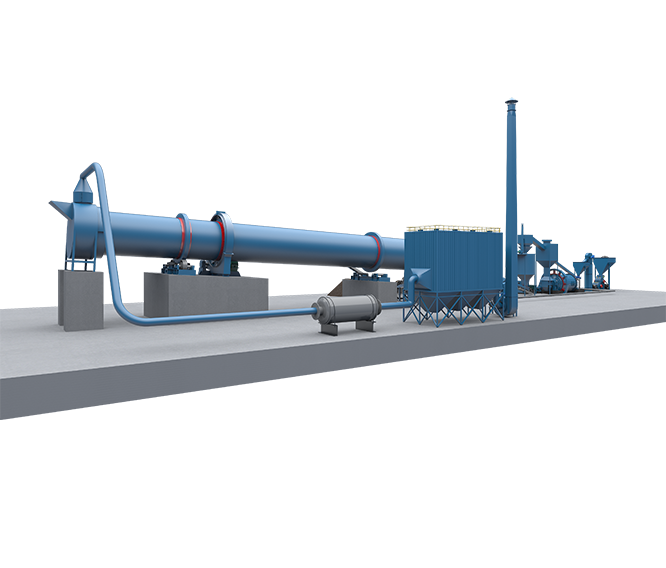

Applied material --- mineral stone, slag, tailings, mineral powder, minerals, silica sand, fluorite powder, feldspar, iron ore, etc.

Made in China

Two weeks delivery, custom cycle, please consult

Industrial dryer machine in mineral processing. The removal of water from solid materials by thermal drying plays a significant role in modern mineral processing. A great number of dryer types are available.

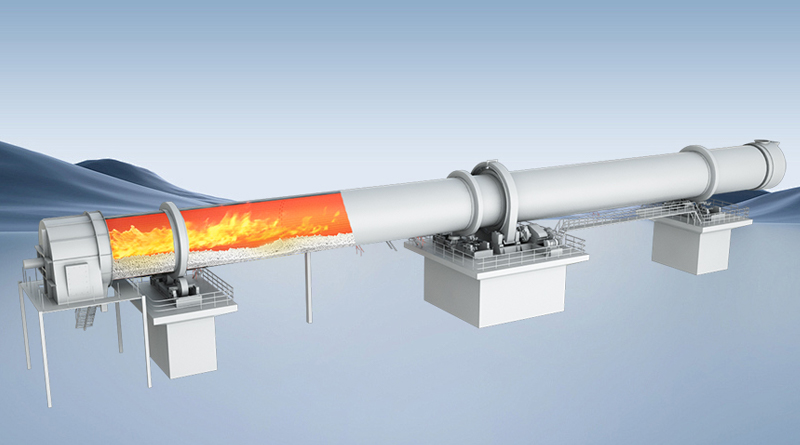

The ore is sent to the hopper by a belt conveyor or bucket elevator, and then enters the feeding end through the feeding pipe through the feeding machine of the hopper. The material is added from the higher end, and the heating medium enters from the lower end, and is in countercurrent contact with the material. When the wet material moves forward in the cylinder, it directly or indirectly receives heat from the heating medium, so that the wet material can be dried, and then sent out through a belt or screw conveyor at the discharge end. In addition, dust collectors can also be used to reduce dust in the drying system.

High thermal efficiency : The thermal efficiency is 80% to 90%. The new internal structure strengthens heat conduction of dispersed materials, and eliminates the sticking phenomenon of the inner wall of the cylinder.

Stable drying quality : Since the heating mode is easy to control, the temperature inside the cylinder and the heat transfer rate of the partition wall can be kept relatively stable.

Long parts life, not easy to wear : The cylinder of the dryer is made of steel material, which has the characteristics of high hardness and high toughness.

Simple operation, environmental protection and energy saving : The dryer system has good sealing performance, and is equipped with a complete dust removal device, with little dust spillage and a good operating environment.

| Spec./m | Shell Cubage | Capacity(t/h) | Installation(%) | Highest Inlet Air Temperature | Main Motor |

| Φ 1.2×8 | 9 | 1.9-2.4 | 3-5 | 700-800 | 7.5 |

| Φ1.2 ×10 | 11.3 | 2.4-3 | 3-5 | 700-800 | 7.5 |

| Φ 1.5×12 | 21.2 | 4.5-5.7 | 3-5 | 700-800 | 15 |

| Φ 1.5×14 | 24.7 | 5.3-6.6 | 3-5 | 700-800 | 15 |

| Φ1.5×15 | 26.5 | 5.7-7.1 | 3-5 | 700-800 | 15 |

| Φ 1.8×12 | 30.5 | 6.5-8.1 | 3-5 | 700-800 | 18.5 |

| Φ 1.8×14 | 35.6 | 7.6-9.5 | 3-5 | 700-800 | 18.5 |

| Φ 2.2×12 | 45.6 | 9.7-12.2 | 3-5 | 700-800 | 22 |

| Φ 2.2×14 | 53.2 | 11.4-14.2 | 3-5 | 700-800 | 22 |

| Φ 2.2×16 | 60.8 | 13-16.2 | 3-5 | 700-800 | 22 |

| Φ 2.4×14 | 63.3 | 13.5-16.9 | 3-5 | 700-800 | 37 |

| Φ 2.4×18 | 81.4 | 17.4-21.7 | 3-5 | 700-800 | 37 |

| Φ 2.4×20 | 90.4 | 19.3-24.1 | 3-5 | 700-800 | 45 |

| Φ 2.4×22 | 99.5 | 21.2-26.5 | 3-5 | 700-800 | 45 |

| Φ 2.6×24 | 127.4 | 27.2-34 | 3-5 | 700-800 | 55 |

| Φ 3×20 | 141.3 | 30.1-37.7 | 3-5 | 700-800 | 75 |

| Φ 3×25 | 176.6 | 37.7-47.1 | 3-5 | 700-800 | 75 |

| Φ 3.2×25 | 201 | 42.9-53.6 | 3-5 | 700-800 | 90 |

| Φ 3.6×28 | 285 | 60.8-76 | 3-5 | 700-800 | 160 |

| Shell diameter × shell Length | Inside diameter of outer shell (mm) |

Inside diameter of inner shell (mm) |

Shell Length (m) |

Shell cubage (m³) |

Shell obliquity | Lifting blade form | Highest inlet air temperature (℃) |

Dimensions (m) |

| Φ1.5×15m | 1500 | 500 | 15 | 20.27 | 3-5% | Lifting form | 850 | 16.2×2.7×2.7 |

| Φ1.5×17m | 17 | 22.97 | 18.2×2.7×2.7 | |||||

| Φ1.5×19m | 19 | 25.68 | 20.0×2.9×2.9 | |||||

| Φ1.8×21m | 1800 | 650 | 21 | 35.91 | 3-5% | Lifting form | 850 | 22.5×2.7×2.7 |

| Φ1.8×23m | 23 | 39.33 | 24.5×2.9×2.9 | |||||

| Φ1.8×25m | 25 | 42.75 | 26.5×2.9×2.9 | |||||

| Φ2.2×21m | 2200 | 800 | 21 | 58.10 | 3-5% | Lifting form | 850 | ---- |

| Φ2.2×23m | 23 | 63.61 | ||||||

| Φ2.2×25m | 25 | 69.15 |

| Spec./m | Capacity(t/h) | Highest Inlet Air Temperature |

| Φ 1.2×8 | 1.9-2.4 | 700-800 |

| Φ1.2 ×10 | 2.4-3 | 700-800 |

| Φ 1.5×12 | 4.5-5.7 | 700-800 |

| Φ 1.5×14 | 5.3-6.6 | 700-800 |

| Φ1.5×15 | 5.7-7.1 | 700-800 |

| Φ 1.8×12 | 6.5-8.1 | 700-800 |

| Φ 1.8×14 | 7.6-9.5 | 700-800 |

| Φ 2.2×12 | 9.7-12.2 | 700-800 |

| Φ 2.2×14 | 11.4-14.2 | 700-800 |

| Φ 2.2×16 | 13-16.2 | 700-800 |

| Φ 2.4×14 | 13.5-16.9 | 700-800 |

| Φ 2.4×18 | 17.4-21.7 | 700-800 |

| Φ 2.4×20 | 19.3-24.1 | 700-800 |

| Φ 2.4×22 | 21.2-26.5 | 700-800 |

| Φ 2.6×24 | 27.2-34 | 700-800 |

| Φ 3×20 | 30.1-37.7 | 700-800 |

| Φ 3×25 | 37.7-47.1 | 700-800 |

| Φ 3.2×25 | 42.9-53.6 | 700-800 |

| Φ 3.6×28 | 60.8-76 | 700-800 |

| Shell diameter × shell Length | Inside diameter of outer shell (mm) |

Inside diameter of inner shell (mm) |

Shell cubage (m³) |

| Φ1.5×15m | 1500 | 500 | 20.27 |

| Φ1.5×17m | 22.97 | ||

| Φ1.5×19m | 25.68 | ||

| Φ1.8×21m | 1800 | 650 | 35.91 |

| Φ1.8×23m | 39.33 | ||

| Φ1.8×25m | 42.75 | ||

| Φ2.2×21m | 2200 | 800 | 58.10 |

| Φ2.2×23m | 63.61 | ||

| Φ2.2×25m | 69.15 |

For customization, please contact us.

Henan Hongxing Mining Machinery Co.,Ltd.(HXJQ) covers an area of 350,000 square menters which includes 260,000 square menters of heavey duty industrial workshops.

covers an area of 350,000 square menters .

heavy duty industrial workshops.

which includes 260,000 square menters.

Is a manufacturer of high-end mining machinery in Asia.

All major ports can deliver goods

All major ports can deliver goods

Two weeks of delivery, custom cycle, please consult.

The International standard for some parts, if there are no relevant accessories in the local area, we provide engineer after-sales service.

Receive after-sales demand

Matching engineer

02Arrived at the scene