- News & Events

- Blog

- Follow us

Made in China

Two weeks delivery, custom cycle, please consult

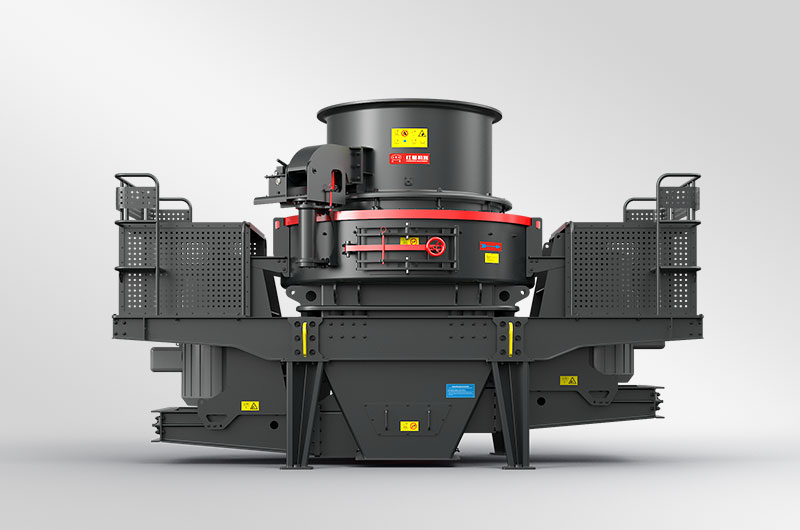

The VSI A7 series impact sand making and shaping machine is a new generation product that draws on advanced technology from similar products both domestically and internationally,and has multiple independent research and development achievements.In the application of large-scale and ultra large machine sand and fine aggregate production lines,it has demonstrated extremely strong performance.

VSI sand making machine uses advanced selective crushing and cleavage crushing principles to directly apply sufficient kinetic energy to the material, and converts the kinetic energy into the crushing energy required to overcome the material through impact to crush it. The material is basically broken along its natural texture surface and cleavage surface, with good particle shape and low self-consumption. Full center feeding: the material falls into the feed hopper and enters the high-speed rotating impeller through the center feed hole. It is rapidly accelerated in the impeller, and its acceleration can reach dozens of times the acceleration of gravity. Then it is ejected from the impeller at high speed, first collides with another part of the material that falls freely after rebounding, and then impacts the material lining (stone hitting stone) or the impact block (stone hitting iron) together, and is rebounded and impacted obliquely upward to the top of the vortex cavity, and then changes its movement direction, deflects and moves downward, and collides with the material emitted from the impeller flow channel to form a continuous material curtain. In this way, a piece of material is subjected to two or more impacts, friction and grinding and crushing in the vortex crushing cavity. The crushed material is discharged from the lower discharge port.

Flexible feeding methods,switching between "waterfall feeding+center feeding" and "full center feeding" modes

The large discharge port design effectively prevents material blockage and improves crushing efficiency

Strengthening the crushing chamber,reducing wear costs,and increasing crushing efficiency

The four impeller design improves the crushing efficiency of the equipment,with a large amount of material passing through and a high yield of finished products

Configure hydraulic cover opening and lifting devices to reduce maintenance difficulty

| Model | Hard material | Soft material | Sand Making | Sand Shaping | Motor Power(kw) |

| Max.Feeding Size (mm) | Throughput(t/h) | ||||

| VSIA7 400 | <40 | <45 | 260-285 | 314-345 | 2×200 |

| VSIA7 500 | <45 | <50 | 340-370 | 405-480 | 2×250 |

| VSIA7 630 | <50 | <55 | 450-488 | 540-590 | 2×315 |

| VSIA7 800 | <50 | <55 | 556-603 | 652-703 | 2×400 |

Note:Processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Sand Making | Sand Shaping | Motor Power(kw) |

| Throughput (t/h) | |||

| VSIA7 400 | 260-285 | 314-345 | 2×200 |

| VSIA7 500 | 340-370 | 405-480 | 2×250 |

| VSIA7 630 | 450-488 | 540-590 | 2×315 |

| VSIA7 800 | 556-603 | 652-703 | 2×400 |

Note:Processing Capacity May Vary With Different Materials And Feeding Sizes.

For customization, please contact us.

Henan Hongxing Mining Machinery Co.,Ltd.(HXJQ) covers an area of 350,000 square menters which includes 260,000 square menters of heavey duty industrial workshops.

covers an area of 350,000 square menters .

heavy duty industrial workshops.

which includes 260,000 square menters.

Is a manufacturer of high-end mining machinery in Asia.

All major ports can deliver goods

All major ports can deliver goods

Two weeks of delivery, custom cycle, please consult.

The International standard for some parts, if there are no relevant accessories in the local area, we provide engineer after-sales service.

Receive after-sales demand

Matching engineer

02Arrived at the scene