- News & Events

- Blog

- Follow us

Application fields: cement, silicate products, new building materials, refractory materials, fertilizers, black and non-ferrous metal mining, and glass ceramics.

Made in China

Two weeks delivery, custom cycle, please consult

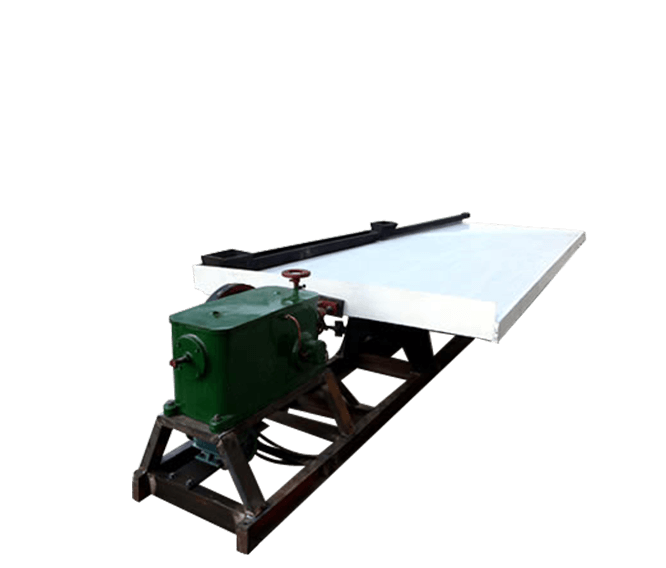

Shaking table is a gravity separation equipment used to separate fine-grained materials.It is widely used to separate tin, tungsten,gold,silver,lead,zinc,tantalum,niobium,iron,manganese,ferrotitanium and coal,etc.Our factory has a long history of producing shakers and has continued to develop and innovate.It has developed from the original straight bed shaker to a single wave surface shaker(in the 1970s),and then to a dual-zone wave surface shaker(in the 1990s).) which greatly improves the shaker's processing capacity,recovery rate and enrichment.

6-S Gold Shaking table, sometimes also known as wet tables, consist of a vibrating riffled deck mounted on some type of support. A motor, usually mounted separately off to the side, drives a small arm that shakes the table along its length. The riffles are usually not more than half an inch high and cover only about half the table surface. Varied riffle designs are available for specific types of applications. Shaking tables are very efficient in recovering heavy minerals from minus 100 microns (150 mesh) down to 5 microns in size.

tin, tungsten, gold, silver, lead, zinc, tantalum, niobium, titanium, manganese, iron ore, coal, etc

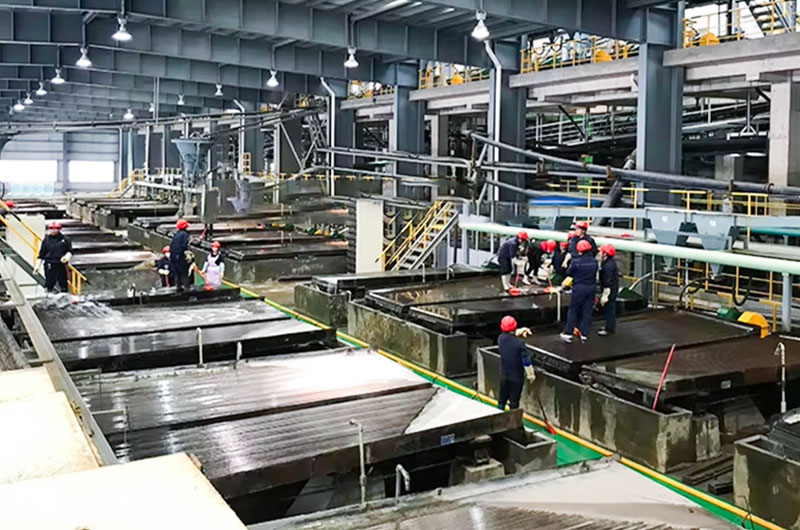

40 years of development history; products are exported to more than 120 countries; more than 2,300 online employees; covering an area of 350,000 square meters.

The company has introduced advanced technology from the United States, Germany, Japan, Australia, and other countries, and established advanced production lines and first-class modern testing plants.

The company has rapidly grown into a mining machinery production and export factory in China with scientific management methods, refined manufacturing processes, and innovative manufacturing concepts.

| Name | Grit concentrator table |

Fine sand concentrator table |

Sludge concentrator table |

|

| Bed surface Dimensions |

Length (mm) |

4450 | 4450 | 4450 |

| Driving part Width (mm) |

1855 | 1855 | 1855 | |

| Concentrate part Width (mm) |

1546 | 1546 | 1546 | |

| Max.feeding size(mm) |

2 | 0.5 | 0.15 | |

| Feeding amount (t/d) |

30-60 | 10-20 | 15-25 | |

| Feeding thickness (%) |

25-30 | 20-25 | 15-25 | |

| Stroke (mm) |

16-22 | 11-16 | 8-16 | |

| Frequency (f) |

45-48 | 48-53 | 50-57 | |

| Bed surface Water quantity (t/d) |

80-150 | 30-60 | 10-17 | |

| Bed surface Horizontal obliquity(°) |

2.5-4.5 | 1.5-3.5 | 1-2 | |

| Bed surface Portrait obliquity(%) |

1.4 | 0.92 | ---- | |

| Table board corner(°) |

32-42 | 40 | 42 | |

| Concentrating area(㎡) |

7.6 | 7.6 | 7.6 | |

| Bed surface Length ratio |

2.6 | 2.6 | 2.6 | |

| Shape of side-bed surface |

Rectangle | Zigzag | Triangle | |

| Motor power(kw) |

1.1 | 1.1 | 1.1 | |

| Transmission device |

Eccentricity Linkage | |||

| Name | Max.feeding size(mm) |

Bed surface Water quantity (t/d) |

| Grit concentrator table |

2 | 80-150 |

| Fine sand concentrator table |

0.5 | 30-60 |

| Sludge concentrator table |

0.15 | 10-17 |

For customization, please contact us.

Henan Hongxing Mining Machinery Co.,Ltd.(HXJQ) covers an area of 350,000 square menters which includes 260,000 square menters of heavey duty industrial workshops.

covers an area of 350,000 square menters .

heavy duty industrial workshops.

which includes 260,000 square menters.

Is a manufacturer of high-end mining machinery in Asia.

All major ports can deliver goods

All major ports can deliver goods

Two weeks of delivery, custom cycle, please consult.

The International standard for some parts, if there are no relevant accessories in the local area, we provide engineer after-sales service.

Receive after-sales demand

Matching engineer

02Arrived at the scene