Chat Online

Chat Online

![]() Production capacity: 1.9-76t/h

Production capacity: 1.9-76t/h

![]() Shell cubage: 9.0-285m³

Shell cubage: 9.0-285m³

![]() Application fields: metallurgy, building materials, light industry, chemical industry

Application fields: metallurgy, building materials, light industry, chemical industry

Applied materials: slag, blast furnace slag, fly ash, cinder, carbide slag, limestone, clay, sand, quartz sand, etc

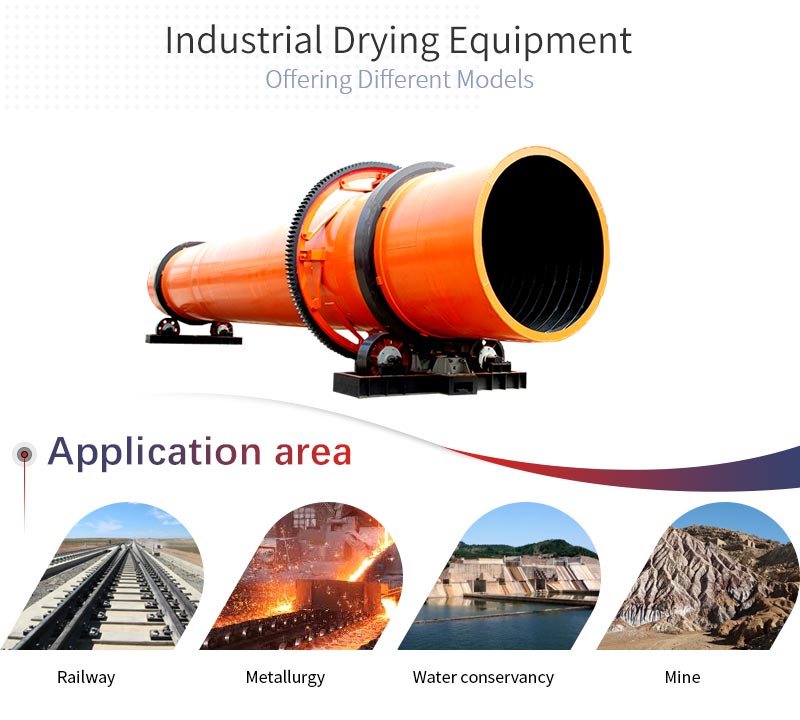

The rotary dryer is a type of industrial dryer employed to reduce or minimize the liquid moisture content of the material it is handling with a heated gas. In industry, rotary dryer is often used to dry metal powder, iron concentrate pellets, slag, quartz sand, blue carbon, lignite, fly ash, quartz sand, clay, etc.

Single drum dryer, double drum dryer, three drum dryer, vertical dryer. The tumble dryer is common drying equipment in the dryer. It has a wide operating range, strong practicability. It is a kind of dryer equipment that users prefer today.

Mainly used in:

1. Chemical, miner, metallurgical and other industries, such as ore, slag, coal, metal powder, clay, diatomaceous earth, kaolin.

2. Agriculture, feed, fertilizer industry, such as straw, pasture, leaves, fish meal, corn sauce, starch residue, distiller's grains, dregs, pomace, soy sauce residue, bagasse, peat, organic compound fertilizer, sludge, aquatic products Waste, food factory waste, slaughterhouse waste, organic fertilizer, inorganic fertilizer, ammonium phosphate.

3. Drying powdery or granular materials with special requirements. Such as various crystals, light calcium carbonate, activated clay, magnetic powder, graphite, inorganic mud, clay, lime slurry, ore mud, phosphate slag, aluminum plant red mud.

1. Simple and reliable operation, a wide range of application, good drying effect.

2. The rotary dryer with high mechanization, especially strong production capability and continuous operation.

3. The rotary dryer is designed with excellent and simple structure, the steady operating process under the resistance of the drum, which is easy to operate.

4. Meets different objectives of customers with High Performance in little malfunction, low maintenance cost, and power consumption.

The dryer is mainly composed of a frame, a heat supply source, a loading machine, a feeding machine, a rotary drum, a material crushing device, a discharging machine, an induced draft fan, a discharger, and a power distribution cabinet.

The power is generated by electric power, diesel power, wind power, flammable materials, etc., and is heated by the ambient air, and is transported to the surrounding area to reach a proper temperature for dehumidification treatment.

The company is headquartered in Zhengzhou High-tech Industrial Development Zone, Henan Province, China, covering a total area of 350,000 square meters, with 260,000 square meters of standardized heavy industrial plants, more than 600 large and medium-sized processing, riveting and assembly equipment, online employees More than 2,300 people, including the level and title of management cadres and engineering and technical personnel more than 400 people.

If you want to know more, such as dryer investment and returns, advantages, costs, fuel consumption, main heat sources, and so on. Please contact us or send an email to info@hxjq.com