Read the next solution

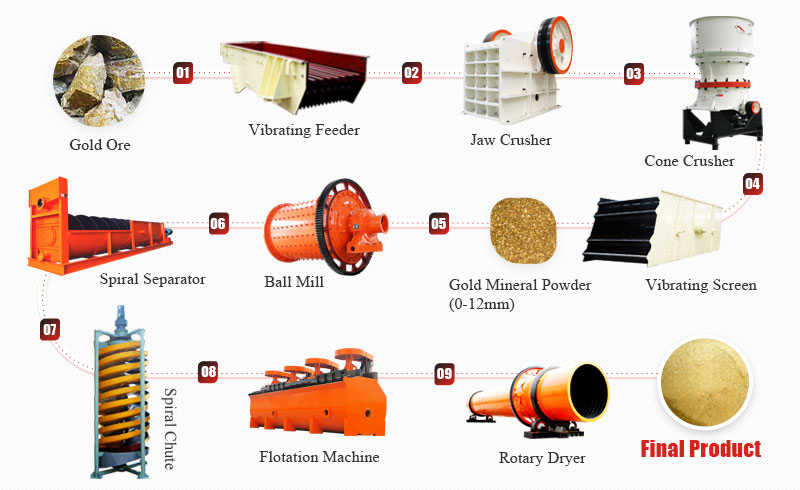

Gold Ore Processing Plant In ZimbabweThe gold ore processing plant and processing technology mainly includes three processes: crushing, milling and beneficiation. Our company's gold ore processing plant has the characteristics of high degree of automation, high breaking rate, low operating cost, energy saving and environmental protection, and fine grain size.

Return to the solution center Back to home page