- News & Events

- Blog

- Follow us

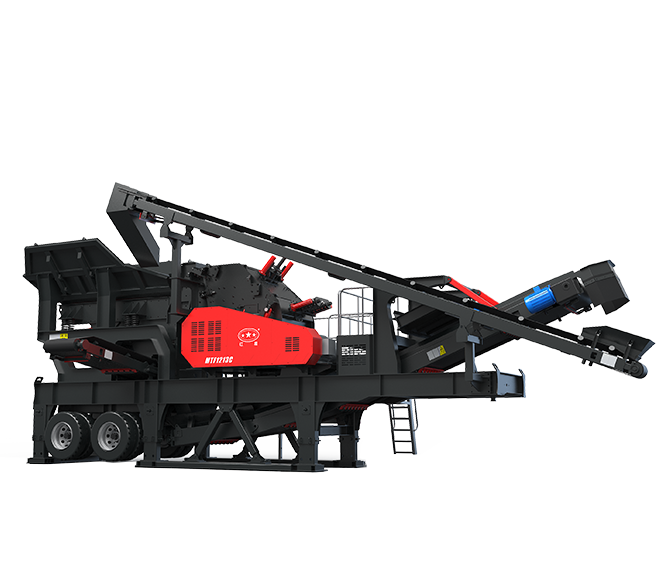

Application fields: mining, stone mining, highway (railway) construction, urban construction waste treatment, etc.

Made in China

Two weeks delivery, custom cycle, please consult

This machine is used to separate materials into various sizes for further processing. The material is separated by passing it through a vibrating screen box which has some different sized screens, or meshes, The materials fall into a sieve and onto attached conveyors which stockpile the end products. The end products can then be used in the building and construction industries.

Wheeled Mobile Screening Station can be used for cement, limestone, granite, basalt, aggregate, calcite, quartz, concrete, dolomite, bluestone, iron ore, coal gangue, construction waste, ferrosilicon. It is widely used in mining, quarry, road (railway) and bridge construction, urban construction waste disposal and other fields.

The material can be evenly transported to the jaw crusher through the feeder. After the primary crushing, the material is sent to the impact crusher through the conveyor for secondary crushing. After crushing, it is output and sent to the vibrating screen. The materials that the conveyor output does not meet the requirements are returned to be crushed again. The whole processing process is a complete production line, which can realize the cyclic crushing of materials and meet the production requirements of customers.

limestone, granite, basalt, quartz, rock, coal, iron ore, gold ore, marble, construction waste, etc.

Finished product specification: 10-350 (unit: mm) Processing materials:

1. Providing high-performance screening box.

2. Screen layers vary from 2 to 4.

3. Has the advantages of low noise, low emissions.

4. Automatic screening movement and adjustment, great screening efficiency.

5. The mobile vibrating screen can be used for the coarse crushing and fine crushing screening system. It can be operated independently by a single unit, or it can be flexibly composed of the system configuration unit.

Different mobile vibrating screens have different price positioning. Also, different manufacturers, equipment configuration and model will also affect the price of equipment, so the price can't be unified. The specific price is based on the actual needs of users. To get the Hongxing mobile vibrating screen offer, you can contact the online customer service staff at any time, or send us an email: sinohxjq@hxjq.com

| Model | HX3S1848 | HX3S1860 | HX3S2160 |

| Transportation Length(mm) | 10280 | 11480 | 11480 |

| Transportation Width(mm) | 2830 | 2830 | 3150 |

| Transportation Height(mm) | 4350 | 4350 | 4350 |

| Maximum Length(mm) | 11100 | 11800 | 11800 |

| Maximum Width(mm) | 3600 | 3600 | 3970 |

| Maximum Height(mm) | 6000 | 6000 | 6500 |

| Weight(t) | 16 | 18 | 19 |

| Tire Configuration | biax fitted | biax fitted | biax fitted |

| Vibrating Screen | 3YZS1848 | 3YZS1860 | 3YZS2160 |

| Model | Transportation Length(mm) |

Transportation Width(mm) |

| HX3S1848 | 10280 | 2830 |

| HX3S1860 | 11480 | 2830 |

| HX3S2160 | 11480 | 3150 |

For customization, please contact us.

Henan Hongxing Mining Machinery Co.,Ltd.(HXJQ) covers an area of 350,000 square menters which includes 260,000 square menters of heavey duty industrial workshops.

covers an area of 350,000 square menters .

heavy duty industrial workshops.

which includes 260,000 square menters.

Is a manufacturer of high-end mining machinery in Asia.

All major ports can deliver goods

All major ports can deliver goods

Two weeks of delivery, custom cycle, please consult.

The International standard for some parts, if there are no relevant accessories in the local area, we provide engineer after-sales service.

Receive after-sales demand

Matching engineer

02Arrived at the scene