Chat Online

Chat Online

![]() Processing ability: 10–280 t/h

Processing ability: 10–280 t/h

![]() Feeding size: 2-0 mm

Feeding size: 2-0 mm

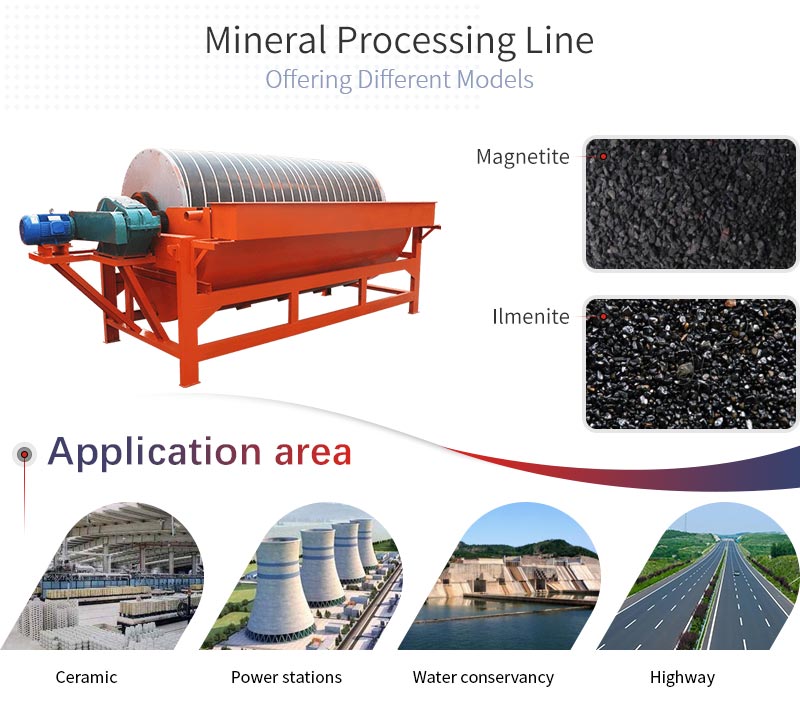

![]() Application fields: wet magnetic separation of magnetite, pyrrhotite, roasting ore, ilmenite and other materials with a particle size of 3 mm or less.

Application fields: wet magnetic separation of magnetite, pyrrhotite, roasting ore, ilmenite and other materials with a particle size of 3 mm or less.

Applied materials: Magnetite, pyrrhotite, calcined ore, ilmenite, etc.

The magnetic separator is applied to conduct the wet-type magnetic separation to process magnetite, pyrrhotite, calcined ore, ilmenite, etc. It can also be used to remove iron from some materials, such as coal, non-metal ores, building materials. The magnetic separator’s magnetic system is made from excellent ferrite or the combination of it and rare earth magnetic steel. The average magnetic induction of the drum surface is 100-600mT. The magnetic separator, made by Hongxing, has many advantages, such as simple structure, big handling capacity, etc.

High magnetic intensity, good magnetic field performance.

Low energy consumption, high processing capacity.

Wide range of applications, high-quality products.

Reasonable structure & good stability, hot sale around the world.

According to magnet type, it can be divided into the permanent magnetic separator and the electromagnetic iron remover.

By the mineral processing methods, it can be divided into the dry-type iron remover and the wet-type iron remover.

By different magnetic systems, there are the drum-type magnetic separator, and the drum roller-type one.

Due to the differences in structure, there are the single-drum magnetic separator, double-type one, and the multi-drum one. There are also some other kinds of classification methods of it.