- News & Events

- Blog

- Follow us

Application fields:metal and non-metallic ore, building materials, artificial sand and various metallurgical slag crushing and shaping.

Made in China

Two weeks delivery, custom cycle, please consult

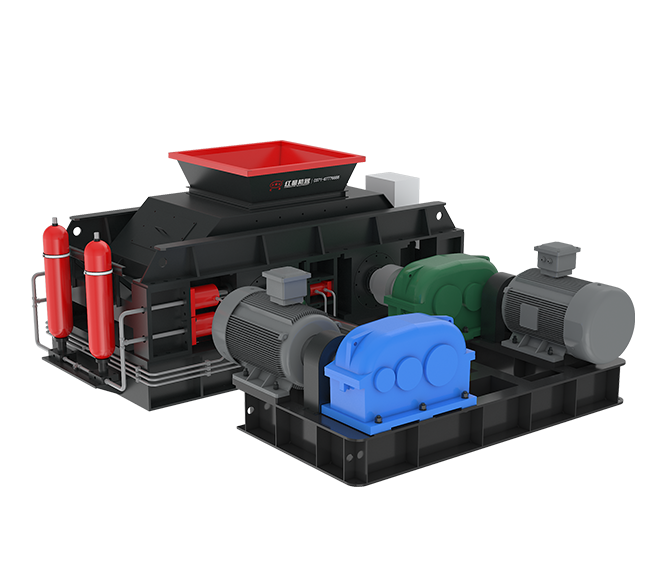

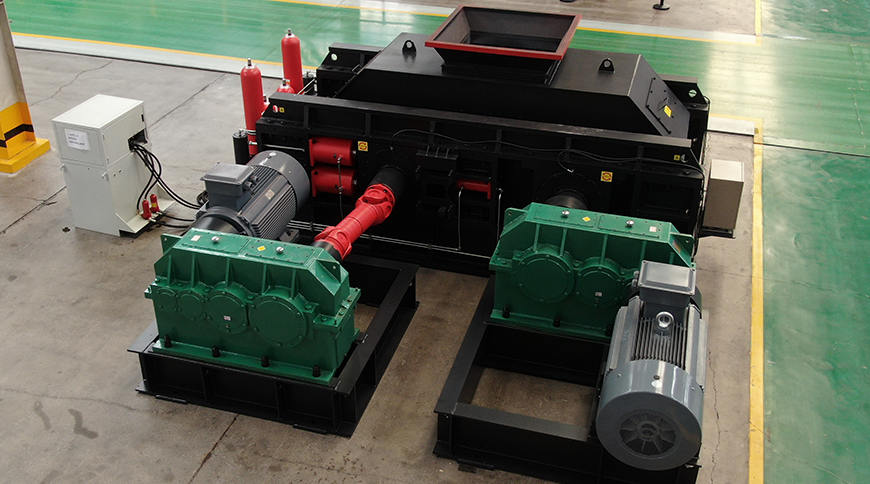

The hydraulic roller crusher through excellent electromechanical and hydraulic integration design,the equipment can operate continuously,stably and reliably.In aggregate and grinding systems,it can generally increase the output by 30%-40%and reduce the total energy consumption by 20%-30%.It can finely crush materials of various hardness In mineral processing,chemical industry,refractory,stone processing,building materials and other industries.

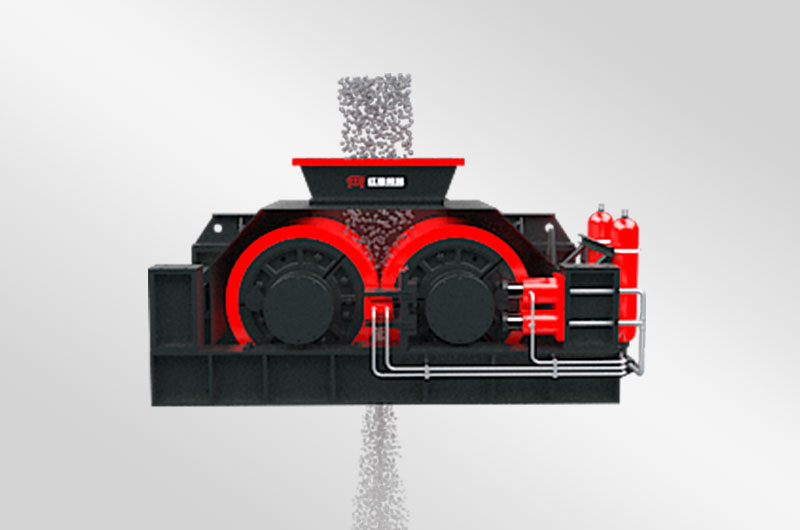

The crushed material falls between the two rollers through the feeding port, where it is squeezed and crushed, and the finished material falls naturally. When encountering hard or unbreakable objects, the rollers can automatically retreat by the action of hydraulic cylinders or springs, increasing the gap between the rollers, allowing the hard or unbreakable objects to fall, thus protecting the machine from damage. There is a certain gap between the two rollers rotating in opposite directions. By changing the gap, the particle size of the product can be controlled.

river pebble, basalt, quartz sand, quartz stone, pebbles, bluestone, granite, etc.

1.Adopting heavy-duty thickened roller skin,wear-resistant and impact resistant,coupled with an automatic lubrication device,greatly prolongs the service life of the components;

2.The equipment is equipped with an automatic control system,which can significantly reduce investment and usage costs compared to other crushing systems with equivalent performance;

3.Ensure stable operation of the roller skin gap between 1-40mm through hydraulic adjustment;

4.Equipped with overload protection,when unbreakable objects enter between the rollers,the rollers automatically avoid and return to the set gap.

| Model | Roller Diameter (mm) | Roller Width (mm) | Maximum Feed Size(mm) | Corresponding processing capacity of discharge port(t/h) | Power(kw) | ||

| 5mm | 10mm | 15mm | |||||

| 2PGY1008 | ø 1000 | 800 | ≤40 | 20-80 | 30-110 | 50-150 | 2×55 |

| 2PGY1210 | ø 1200 | 1000 | ≤60 | 25-100 | 50-180 | 80-240 | 2×90 |

| 2PGY1510 | ø 1500 | 1000 | ≤80 | 30-130 | 60-240 | 90-330 | 2×160 |

| 2PGY1810 | ø 1800 | 1000 | ≤100 | 40-170 | 80-320 | 120-450 | 2×250 |

| 2PGY2012 | ø 2000 | 1200 | ≤120 | 60-220 | 110-400 | 170-600 | 2×315 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Maximum Feed Size(mm) | Corresponding processing capacity of discharge port(t/h) | ||

| 5mm | 10mm | 15mm | ||

| 2PGY1008 | ≤40 | 20-80 | 30-110 | 50-150 |

| 2PGY1210 | ≤60 | 25-100 | 50-180 | 80-240 |

| 2PGY1510 | ≤80 | 30-130 | 60-240 | 90-330 |

| 2PGY1810 | ≤100 | 40-170 | 80-320 | 120-450 |

| 2PGY2012 | ≤120 | 60-220 | 110-400 | 170-600 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

For customization, please contact us.

Henan Hongxing Mining Machinery Co.,Ltd.(HXJQ) covers an area of 350,000 square menters which includes 260,000 square menters of heavey duty industrial workshops.

covers an area of 350,000 square menters .

heavy duty industrial workshops.

which includes 260,000 square menters.

Is a manufacturer of high-end mining machinery in Asia.

All major ports can deliver goods

All major ports can deliver goods

Two weeks of delivery, custom cycle, please consult.

The International standard for some parts, if there are no relevant accessories in the local area, we provide engineer after-sales service.

Receive after-sales demand

Matching engineer

02Arrived at the scene