- News & Events

- Blog

- Follow us

Application fields:It is widely used in ore crushing, railways, highways, large-scale water conservancy and hydropower, construction engineering, machine sand production, dry mortar, concrete mixing stations, and other fields.

Made in China

Two weeks delivery, custom cycle, please consult

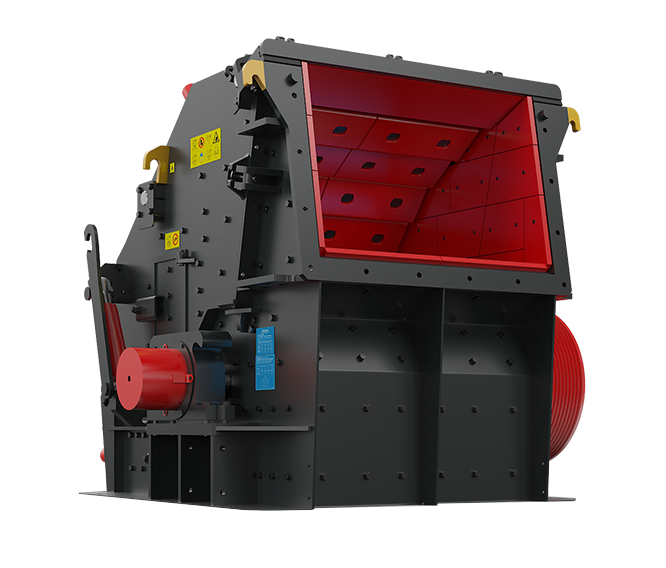

The HX series impact crusher is suitable for coarse, medium and fine crushing of medium hardness and brittle materials. It is a good choice for industrial applications such as railway, highway, building aggregate, and construction waste recycling

The rugged heavy-duty rotor structure of the CI series impact crusher increases equipment throughput and crushing ratio. The high quality welded construction ensures that the machine can withstand the most impact and achieve good crushing results. The CI1213 impact crusher is a hot sale model of the CI series. Its production capacity is 100-280t/h, the power is 200kw, the rotor specification is φ1200*1300mm, and the feed size can meet the 300mm feeding material.

It is widely used in ore crushing, railways, highways, large-scale water conservancy and hydropower, construction engineering, machine sand production, dry mortar, concrete mixing stations, and other fields.

Finished product specification: 10-350 (unit: mm) Processing materials:

1. With a simple configuration, it can achieve coarse/medium crushing, fixing/mobile configure.

2. The two-stage crushing cavity of the impact crusher has realized the crushing ratio that can be achieved by the traditional three-stage impact crushing cavity.

3. The unique locking structure has a good impact and wear resistance and keeps the discharge size stable.

4. The space between the counter plate and the counter hammer is easy to adjust by hydraulic equipment.

The material is evenly conveyed to the jaw crusher through the feeder, and after the first crushing of jaw crusher, it is sent to the impact crusher for secondary crushing. The crushed material is sieved by vibrating screen, and the material that meets the crushing requirement is output by the conveyor. The material that does not meet the requirement will be sent to the impact crusher for crushing again. The entire crawler-type mobile jaw crusher + impact crusher station can form a closed-circuit system through a circular vibrating screen to realize the cyclical crushing of materials, and the finished materials are output by the conveyor for continuous crushing operations.

HX Series Counterattack Break Secondary Counterattack Break (Fine Break)

| Model | Maximum Feeding Size(mm) | Crusher weight Containing hopper(kg) |

Power(kw) | Processing capacity(t/h) |

| HX100S | 300 | 11380 | 160 | 60-210 |

| HX120S | 350 | 18112 | 200 | 80-300 |

| HX140S | 350 | 29650 | 400 | 150-700 |

HX Series Counter-break Primary Counter-break (Coarse Break) Applicable to Construction Waste Crushing

| Model | Maximum Feeding Size(mm) | Crusher weight Containing hopper(kg) |

Power(kw) | Processing capacity(t/h) |

| HX100P | 600 | 10940 | 160 | 60-210 |

| HX120P | 900 | 17252 | 200 | 80-400 |

| HX140P | 1000 | 27750 | 315 | 200-700 |

HX Series Counterattack Break Secondary Counterattack Break (Fine Break)

Containing hopper(t)

| Model | Maximum Feeding Size(mm) | Power(kw) | Processing capacity(t/h) |

| HX100S | 300 | 160 | 60-210 |

| HX120S | 350 | 200 | 80-300 |

| HX140S | 350 | 400 | 150-700 |

HX Series Counter-break Primary Counter-break (Coarse Break) Applicable to Construction Waste Crushing

| Model | Maximum Feeding Size(mm) | Power(kw) | Processing capacity(t/h) |

| HX100P | 600 | 160 | 60-210 |

| HX120P | 900 | 200 | 80-400 |

| HX140P | 1000 | 315 | 200-700 |

For customization, please contact us.

Henan Hongxing Mining Machinery Co.,Ltd.(HXJQ) covers an area of 350,000 square menters which includes 260,000 square menters of heavey duty industrial workshops.

covers an area of 350,000 square menters .

heavy duty industrial workshops.

which includes 260,000 square menters.

Is a manufacturer of high-end mining machinery in Asia.

All major ports can deliver goods

All major ports can deliver goods

Two weeks of delivery, custom cycle, please consult.

The International standard for some parts, if there are no relevant accessories in the local area, we provide engineer after-sales service.

Receive after-sales demand

Matching engineer

02Arrived at the scene