- News & Events

- Blog

- Follow us

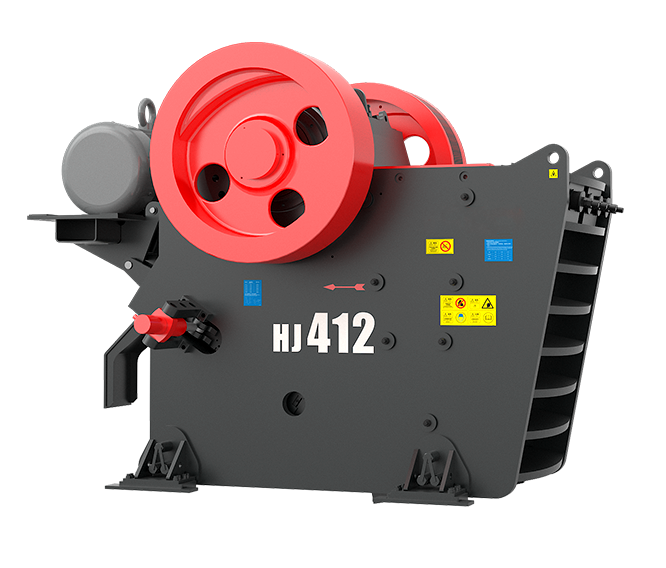

Application fields: metallurgy, chemical, building materials, electricity, transportation and other departments.

Made in China

Two weeks delivery, custom cycle, please consult

Concrete crusher can be used to process over 120 kinds of stones in mining, quarry, etc. The crushed stones have wide market demand in many industries, such as construction, building, road, highway, water conservancy and other fields.

Crusher Types---We have small, medium and large stone crusher for sale, stationary & mobile types for choice, meeting your different needs.

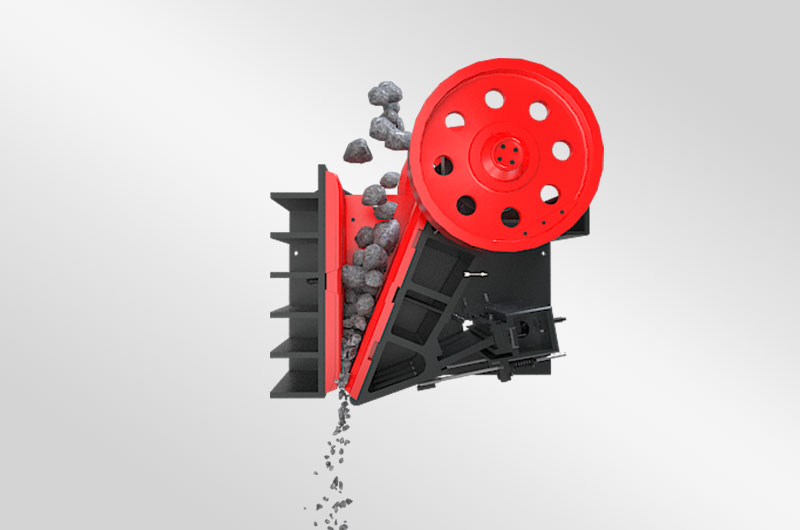

The motor drives the belt and pulley, and the movable jaw moves up and down through the eccentric shaft. When the movable jaw rises, the angle between the toggle plate and the movable jaw becomes larger, thereby pushing the movable jaw approaches the fixed jaw, and at the same time, the material is crushed to achieve the purpose of crushing; when the movable jaw descends, the angle between the toggle and the movable jaw becomes smaller. Under the role of pull rod and the spring, the movable jaw leaves the fixed jaw, the crushed materials are discharged from the lower mouth of the crushing cavity. With the continuous rotation of motor and the periodic motion of movable jaw, realizing mass production.

barite, calcite, coal, concrete, aggregate, gravel, basalt, cement, gypsum, limestone, granite, rock and so on.

Finished product specification: 10-350 (unit: mm) Processing materials:

1. Simple structure, convenient installation and maintenance, and lower running cost.

2. The percentage of water can reach the level of 8% after the material being crushed.

3. Cubic product shape, lower flakiness content.

4. Accumulation density, less iron pollution.

As a professional manufacturer of construction and mining crushing solutions, we can provide our customers with high-quality building and mine crushing equipment and provide detailed technical support. According to the specific requirements of customers, we offer the tailor-made overall design and construction plan. Different process requirements are met through an optimized combination of various types of equipment.

Different types and sizes of concrete crushers are available at different prices. If you need our latest offer, you can tell us the specific type and quantity you want. We have the most professional technical people here to provide you with a complete solution. You can contact us at sinohxjq@hxjq.com. You can also consult us online or leave your contact information and project information in the message box below, such as materials, capacity and so on. We will contact you as soon as possible!

| Model | Feed opening size(mm) | Max.Feeding size (mm) | Adjustment range of discharge port (mm) | Capacity(t/h) | Rotation speed of eccentric shaft(r/min) | Power (kw) | Dimensions(L×W×H) (mm) |

| PE 150×250 | 150×250 | 125 | 10-40 | 1-3 | 268 | 4P 5.5 | 760×700×860 |

| PE 200×300 | 200×300 | 180 | 15-50 | 2-6 | 260 | 4P 7.5 | 915×780×990 |

| PE 200×350 | 200×350 | 180 | 18-60 | 3-10 | 276 | 4P 11 | 1000×914×1112 |

| PE 250×400 | 250×400 | 210 | 20-70 | 5-21 | 300 | 6P 15 | 1100×1032×1285 |

| PE 400×600 | 400×600 | 340 | 40-100 | 16-64 | 270 | 6P 30 | 1623×1736×1615 |

| PE 500×750 | 500×750 | 425 | 50-100 | 40-110 | 268 | 6P 55 | 1920×1850×1920 |

| PE 600×750 | 600×750 | 500 | 150-200 | 80-240 | 268 | 6P 55 | 2020×1850×1920 |

| PE 600×900 | 600×900 | 500 | 65-160 | 50-160 | 254 | 6P 55 | 2530×1900×2340 |

| PE 750×1060 | 750×1060 | 630 | 80-180 | 110-320 | 245 | 8P 110 | 2680×2380×2785 |

| PE 900×1200 | 900×1200 | 750 | 100-200 | 220-380 | 208 | 8P 110 | 3470×2876×3330 |

| PE1200×1500 | 1200×1500 | 1020 | 150-350 | 400-1000 | 180 | 8P 160-245 | 4850×3220×3680 |

| PE1500×1800 | 1500×1800 | 1200 | 220-350 | 500-1200 | 180 | 8P 280-380 | 5160×3660×4248 |

| PEX 150×750 | 150×750 | 120 | 18-48 | 8-25 | 320 | 4P 15 | 1170×1575×1030 |

| PEX 250×750 | 250×750 | 210 | 25-60 | 13-35 | 320 | 6P 22 | 1550×1730×1470 |

| PEX 250×1000 | 250×1000 | 210 | 25-60 | 16-52 | 330 | 6P 30 | 1580×2006×1390 |

| PEX 250×1200 | 250×1200 | 210 | 25-60 | 20-61 | 330 | 6P 37 | 1780×2214×1430 |

| PEX 300×1300 | 300×1300 | 250 | 20-90 | 16-105 | 300 | 6P 55 | 2210×2320×1723 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Feeding size(mm) | Maximum feeding size (mm) | Range of discharging port(mm) | Handling capacity(t/h) | Power(kw) | Width×Length×Height (mm) |

| HD72(57) | 460×720 | 425 | 45-100 | 50-120 | 6P 55 | 1566×1965×1630 |

| HD86(69) | 580×860 | 500 | 50-150 | 60-210 | 8P 75 | 1722×1943×1810 |

| HD98(751) | 680×980 | 630 | 75-175 | 110-330 | 8P 110 | 1960×2470×2180 |

| HD110(912) | 850×1100 | 750 | 100-200 | 230-450 | 6P 132 | 2381×2775×2500 |

| HD125 | 950×1250 | 900 | 125-225 | 280-750 | 8P 160 | 2600×3320×3120 |

| Model | Maximum Feeding size(mm) | Feeding opening size L×W(mm) | Adjustment range of discharge port(mm) | Capacity(t/h) | Power(KW) | Dimensions L×W×H(mm) |

| CJ96 | 480 | 930×580 | 60-175 | 105-390 | 4P 90 | 2850×2270×1950 |

| CJ106 | 560 | 1060×700 | 70-200 | 150-500 | 4P 110 | 3280×2580×2400 |

| CJ120 | 700 | 1200×870 | 70-200 | 175-610 | 4P 160 | 3700×2790×2950 |

| CJ125 | 760 | 1250×950 | 100-250 | 270-831 | 4P 160 | 4230×2780×2960 |

| CJ150 | 960 | 1400×1200 | 125-250 | 340-880 | 4P 200 | 5030×3440×3970 |

| CJ160 | 960 | 1600×1200 | 150-300 | 430-1145 | 4P 250 | 5780×3460×3580 |

| CJ200 | 1200 | 2000×1500 | 175-300 | 630-1435 | 6P 400 | 6600×4030×4400 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Max.Feeding size (mm) | Capacity (t/h) |

| PE 150×250 | 125 | 1-3 |

| PE 200×300 | 180 | 2-6 |

| PE 200×350 | 180 | 3-10 |

| PE 250×400 | 210 | 5-21 |

| PE 400×600 | 340 | 16-64 |

| PE 500×750 | 425 | 40-110 |

| PE 600×750 | 500 | 80-240 |

| PE 600×900 | 500 | 50-160 |

| PE 750×1060 | 630 | 110-320 |

| PE 900×1200 | 750 | 220-380 |

| PE 1200×1500 | 1020 | 400-1000 |

| PE 1500×1800 | 1200 | 500-1200 |

| PEX 150×750 | 120 | 8-25 |

| PEX 250×750 | 210 | 13-35 |

| PEX 250×1000 | 210 | 16-52 |

| PEX 250×1200 | 210 | 20-61 |

| PEX 300×1300 | 250 | 16-105 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Feeding size(mm) |

Maximum feeding size(mm) |

Handling capacity (t/h) |

| HD72(57) | 460×720 | 425 | 50-120 |

| HD86(59) | 580×860 | 500 | 60-210 |

| HD98(751) | 680×980 | 630 | 110-330 |

| HD110(912) | 850×1100 | 750 | 230-450 |

| HD125 | 950×1250 | 900 | 280-750 |

| Model | Maximum Feeding size(mm) | Capacity(t/h) |

| CJ96 | 480 | 105-390 |

| CJ106 | 560 | 150-500 |

| CJ120 | 700 | 175-610 |

| CJ125 | 760 | 270-831 |

| CJ150 | 960 | 340-880 |

| CJ160 | 960 | 430-1145 |

| CJ200 | 1200 | 630-1435 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

For customization, please contact us.

Henan Hongxing Mining Machinery Co.,Ltd.(HXJQ) covers an area of 350,000 square menters which includes 260,000 square menters of heavey duty industrial workshops.

covers an area of 350,000 square menters .

heavy duty industrial workshops.

which includes 260,000 square menters.

Is a manufacturer of high-end mining machinery in Asia.

All major ports can deliver goods

All major ports can deliver goods

Two weeks of delivery, custom cycle, please consult.

The International standard for some parts, if there are no relevant accessories in the local area, we provide engineer after-sales service.

Receive after-sales demand

Matching engineer

02Arrived at the scene