- News & Events

- Blog

- Follow us

Application range: widely used in cement building materials, thermal power generation, metallurgical industry, chemical industry, etc.

Made in China

Two weeks delivery, custom cycle, please consult

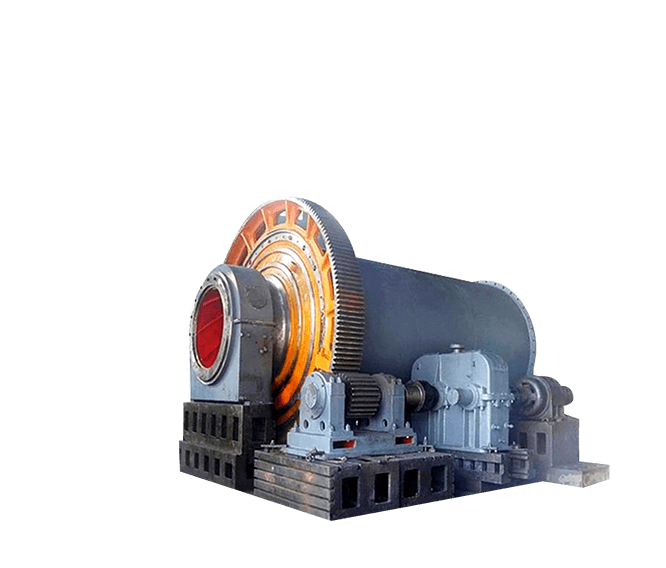

The coal mill is the main equipment of coal powder preparation system. A coal mill is a machine for crushing coal and grinding it into pulverized coal. It is also suitable for cement building materials, thermal power generation, metallurgy, chemical industry, etc.

cement, silicate, refractory, fertilizer, ferrous and non-ferrous metal beneficiation.

1. Coal mill shows strong adaptability to materials, and it can grind coal of various hardness.

2. Coal mill is capable of continuous production, large production capacity, which improves profitability for you.

Its fineness is easy to adjust, and it is to install and maintain

3. Coal mill with compact structure, stable operation, long service life, and other characteristics, to ensure that the machine runs in the way you need.

This coal mill adopts edge driving and the electromotor drives the grinding mill through the reducer and rack wheel and pinion. The coal mill adopts air-swept structure with a drying bin so that it had strong adaptability to the water containing in the raw coal. Inside the powder grinding cabin, the ladder lining board, double-ladder lining board, and ripple lining board are arranged in a combined type, thus improving the powder grinding ability of the coal mill. The feeding device adopts a window-shade structure that the air can obliquely go in, thus enhancing the heat exchange ability of the grinding mill and effectively avoiding the material blockage of the feeding mouth of the coal mill.

| (Dia.×Length) (m) |

Speed (r/min) |

Griding Media Loading (t) |

Main Motor (KW) |

Main Reducer |

| Φ1.7×2.5 | 24.5 | 7.5 | 95 | ZD40-8 |

| Φ1.8×(3+1.5) | 25 | 7.8 | 95 | ZD40-10 |

| Φ2.2×3 | 22 | 13 | 180 | ZD50-9 |

| Φ2.2×4.4 | 22.4 | 19 | 240 | ZD60-11 |

| Φ2.4×(4.5+2) | 20.4 | 20.8 | 355 | ZD70-8 |

| Φ2.4×4.75 | 20.4 | 22 | 280 | ZD60-8 |

| Φ2.6×(5.25+2.25) | 19.7 | 28 | 400 | ZDY400 |

| Φ2.8×(5+3) | 18.7 | 32 | 500 | MBY560 |

| Φ2.8×(5.75+2.25) | 18.7 | 34 | 500 | MBY560 |

| Φ3×(6.5+2.5) | 18.3 | 43 | 630 | MBY560 |

| Φ3.2×(6.5+2) | 17.08 | 50 | 710 | MBY630 |

| Φ3.2×(7+2.5) | 17.08 | 55 | 710 | MBY630 |

| Φ3.4×(6+3) | 17.47 | 54 | 900 | MBY800 |

| Φ3.4×(6.5+2.5) | 17.47 | 54 | 900 | JDX-80 |

| Φ3.5×8 | 17.2 | 80 | 1000 | MBY800 |

| Φ3.8×(7+2.5) | 16.7 | 75.5 | 1250 | MBY(X)800 |

| Φ3.8×(7.5+3) | 16.7 | 80 | 1400 | JDX-90 |

| Φ3.8×(7.75+3.5) | 16.7 | 85 | 1400 | JDX-90 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| (Dia.×Length) (m) |

Speed (r/min) |

Griding Media Loading (t) |

| Φ1.7×2.5 | 24.5 | 7.5 |

| Φ1.8×(3+1.5) | 25 | 7.8 |

| Φ2.2×3 | 22 | 13 |

| Φ2.2×4.4 | 22.4 | 19 |

| Φ2.4×(4.5+2) | 20.4 | 20.8 |

| Φ2.4×4.75 | 20.4 | 22 |

| Φ2.6×(5.25+2.25) | 19.7 | 28 |

| Φ2.8×(5+3) | 18.7 | 32 |

| Φ2.8×(5.75+2.25) | 18.7 | 34 |

| Φ3×(6.5+2.5) | 18.3 | 43 |

| Φ3.2×(6.5+2) | 17.08 | 50 |

| Φ3.2×(7+2.5) | 17.08 | 55 |

| Φ3.4×(6+3) | 17.47 | 54 |

| Φ3.4×(6.5+2.5) | 17.47 | 54 |

| Φ3.5×8 | 17.2 | 80 |

| Φ3.8×(7+2.5) | 16.7 | 75.5 |

| Φ3.8×(7.5+3) | 16.7 | 80 |

| Φ3.8×(7.75+3.5) | 16.7 | 85 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

For customization, please contact us.

Henan Hongxing Mining Machinery Co.,Ltd.(HXJQ) covers an area of 350,000 square menters which includes 260,000 square menters of heavey duty industrial workshops.

covers an area of 350,000 square menters .

heavy duty industrial workshops.

which includes 260,000 square menters.

Is a manufacturer of high-end mining machinery in Asia.

All major ports can deliver goods

All major ports can deliver goods

Two weeks of delivery, custom cycle, please consult.

The International standard for some parts, if there are no relevant accessories in the local area, we provide engineer after-sales service.

Receive after-sales demand

Matching engineer

02Arrived at the scene