Read the next article

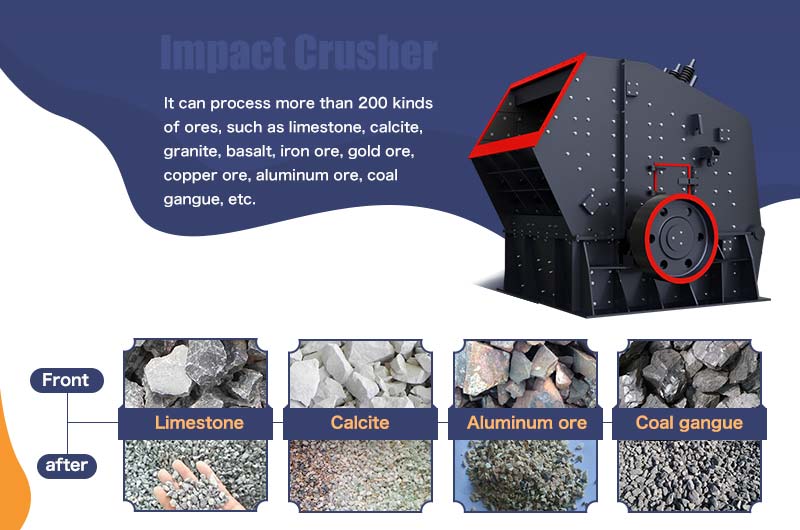

So Many Crusher Equipment, There Is Always One for YourThere are many kinds of crusher machines, and each kind of crusher has different specification according to the different feeding size and output need. Users can consult in detail according to the needs of their own production lines and the degree of material to be crushed.

Return to the news center Back to home page